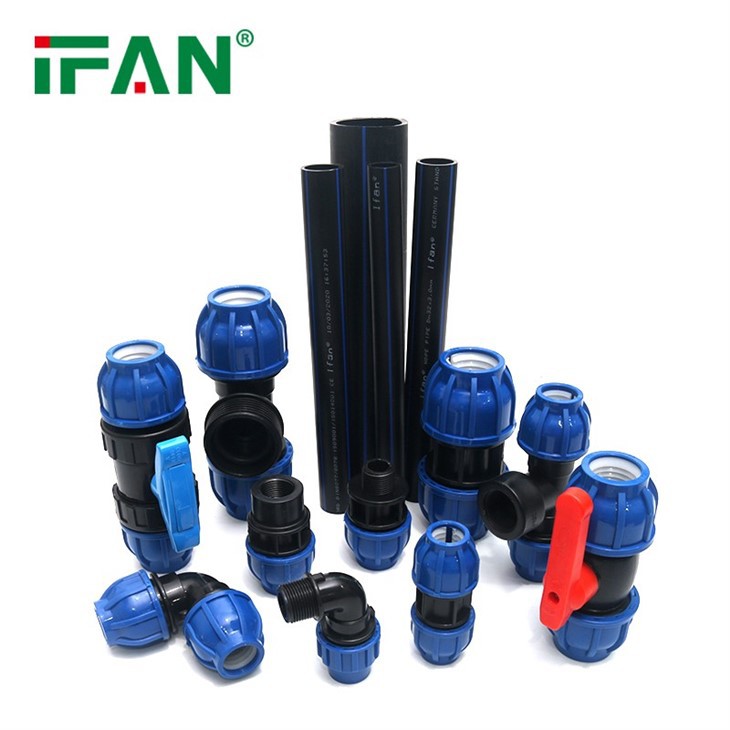

ASTM D3350 All Type HDPE Fitting

Material: HDPE

Color:Blue

Size: Customized

Brand: IFAN

Sample: Free

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN's product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

High-Density Polyethylene (HDPE) fittings have become integral components in contemporary infrastructure projects due to their exceptional properties and versatility. These fittings are essential for a range of applications, including water supply, drainage systems, and industrial pipelines. Their importance in modern infrastructure can be explored through various aspects such as durability, corrosion resistance, ease of installation, cost-effectiveness, and environmental impact.

Durability and Strength

One of the primary reasons for the widespread use of HDPE fittings in infrastructure projects is their durability. HDPE material is renowned for its high tensile strength and flexibility, which allows it to withstand significant physical stress and pressure. Unlike traditional materials such as metal or concrete, HDPE fittings do not become brittle over time. They are resistant to cracking and can endure extreme temperature fluctuations without compromising their integrity. This durability ensures that HDPE fittings maintain their performance over long periods, making them ideal for demanding applications in infrastructure projects.

Corrosion and Chemical Resistance

Another critical advantage of HDPE fittings is their resistance to corrosion and chemical attack. In contrast to metal fittings, which can corrode and degrade when exposed to moisture and chemicals, HDPE fittings remain unaffected by these environmental factors. This resistance makes them particularly valuable in systems that handle aggressive chemicals or are subject to harsh environmental conditions. For example, in wastewater treatment plants or chemical processing facilities, HDPE fittings ensure a longer service life and reduced maintenance needs, contributing to the overall efficiency and reliability of the infrastructure.

Ease of Installation and Flexibility

HDPE fittings are known for their ease of installation, which is a significant benefit in large-scale infrastructure projects. The lightweight nature of HDPE compared to traditional materials simplifies handling and reduces labor costs during installation. Additionally, HDPE fittings can be joined using various methods, such as socket fusion and butt fusion, which create strong, seamless joints. This flexibility in installation techniques not only speeds up the process but also enhances the reliability of the pipeline systems. The ability to adapt to complex layouts and configurations makes HDPE fittings suitable for diverse infrastructure requirements.

Cost-Effectiveness and Longevity

The cost-effectiveness of HDPE fittings is another factor that contributes to their popularity in infrastructure projects. While the initial cost of HDPE fittings may be higher than some traditional materials, their long-term benefits outweigh the initial investment. HDPE fittings require minimal maintenance and have a long service life, reducing the need for frequent replacements and repairs. This longevity translates to lower overall lifecycle costs, making HDPE fittings a cost-effective choice for large-scale projects where budget constraints are a consideration.

Environmental Impact and Sustainability

The environmental impact of using HDPE fittings is a key consideration in modern infrastructure development. HDPE is a recyclable material, which means that at the end of its service life, it can be processed and reused, contributing to sustainability efforts. Furthermore, the production of HDPE fittings involves fewer environmental pollutants compared to some traditional materials. By incorporating HDPE fittings into infrastructure projects, stakeholders can contribute to more sustainable construction practices and reduce the overall environmental footprint of their projects.

Conclusion

In summary, HDPE fittings play a vital role in modern infrastructure projects due to their exceptional durability, resistance to corrosion, ease of installation, cost-effectiveness, and environmental benefits. Their ability to perform reliably under various conditions makes them a preferred choice for a wide range of applications, from water supply systems to industrial pipelines. As infrastructure projects continue to evolve, the advantages offered by HDPE fittings will likely reinforce their importance and contribute to more efficient, sustainable, and cost-effective infrastructure solutions.

Hot Tags: astm d3350 all type hdpe fitting, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, PEX Fitting, Aluminum PPR Pipe, Green Plastic PPR Pipe, PEX AL PEX Pipe Overlap, Sanitary Product, PPR Fitting Female Union

Send Inquiry