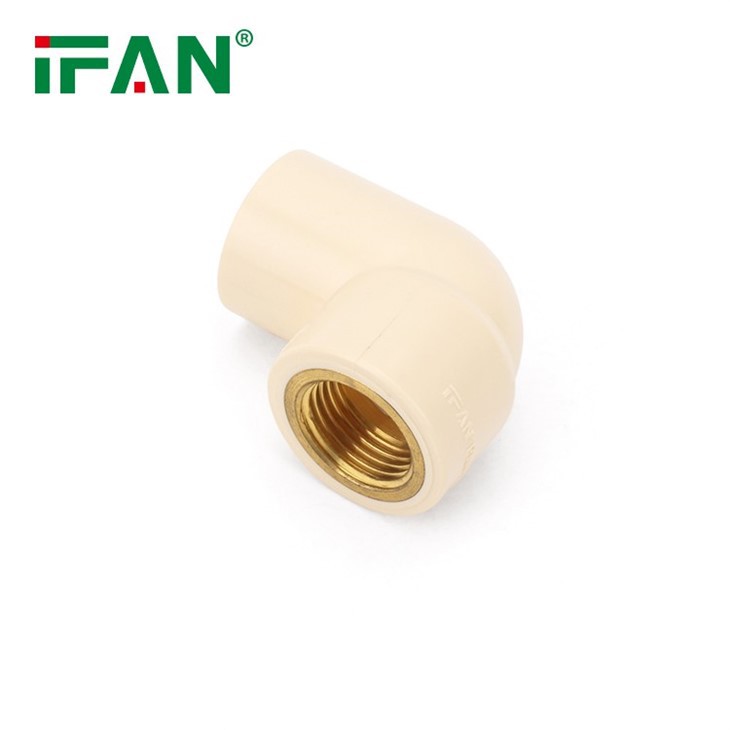

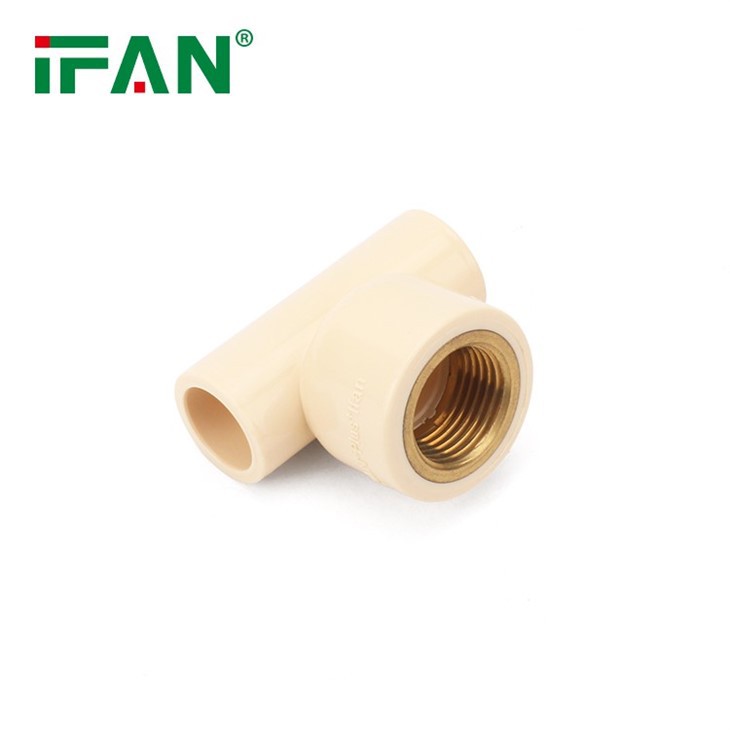

CPVC Plumbing Pipe Fitting

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN's product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

Precision Injection Molding and Surface Smoothness Control in CPVC Pipe Fittings

Introduction: The Importance of Precision in Injection Molding for CPVC Pipe Fittings

Precision injection molding is an essential manufacturing process for producing high-quality CPVC pipe fittings. This process involves injecting molten CPVC material into a mold with extreme accuracy, ensuring that the fittings produced have consistent dimensions, durability, and smooth surfaces. One of the key factors in achieving high-performance CPVC pipe fittings is maintaining excellent surface smoothness, which not only enhances the aesthetic appeal of the fittings but also improves their performance in terms of flow efficiency and resistance to wear. IFAN brand CPVC pipe fittings leverage advanced precision injection molding techniques, ensuring superior surface smoothness and overall product quality. In comparison, ERA's CPVC fittings are manufactured with less advanced molding processes, leading to surface imperfections and reduced product consistency.

Precision Molding Process: Enhancing Structural Integrity and Consistency

IFAN's precision injection molding process is designed to produce CPVC pipe fittings with high dimensional accuracy, ensuring that each fitting meets rigorous quality standards. This precision in molding allows for a tighter fit in pipe connections, reducing the risk of leaks or failures over time. The molding process is also optimized to ensure that the material flow is uniform, reducing the chances of defects such as air pockets or voids within the fittings. ERA, on the other hand, uses less precise molding techniques, which can result in slight variations in the dimensions and material consistency of their CPVC fittings. This can lead to issues such as poor sealing and higher potential for product failure when compared to the highly accurate molds used by IFAN.

Surface Smoothness Control: Enhancing Flow Efficiency and Durability

A smooth surface on CPVC pipe fittings is crucial for reducing friction and improving the flow of fluids within the pipes. IFAN's advanced injection molding process includes stringent surface smoothness control, ensuring that each fitting produced has a flawless finish. This smooth surface reduces turbulence in the fluid flow, leading to greater efficiency and lower energy consumption in piping systems. Additionally, a smooth surface minimizes the potential for material buildup or scaling within the pipes, which can reduce the lifespan of the system. In contrast, ERA's less refined molding process often results in fittings with rougher surfaces, increasing the likelihood of fluid turbulence, energy loss, and the accumulation of deposits inside the pipes, ultimately affecting the long-term performance of their fittings.

Material Flow Optimization: Reducing Defects and Enhancing Product Quality

The ability to optimize material flow during the injection molding process is another key factor that contributes to the high quality of IFAN's CPVC pipe fittings. By carefully controlling the temperature, pressure, and speed of the injection, IFAN ensures that the material flows evenly into every part of the mold, preventing defects such as warping, sink marks, or flow lines. This optimization process also contributes to the strength and durability of the fittings, ensuring that they can withstand high-pressure applications without compromising their structural integrity. ERA's injection molding process is less efficient in terms of material flow optimization, leading to products that may suffer from imperfections or structural weaknesses that can affect their performance in demanding applications.

Durability and Performance: The Impact of High-Quality Molding on Product Lifespan

The precision in IFAN's injection molding process directly correlates with the durability and performance of the CPVC pipe fittings. By ensuring that each fitting is manufactured with consistent dimensions and a smooth surface, IFAN guarantees a longer product lifespan and enhanced resistance to wear and tear. The high-quality molding process also contributes to the fittings' resistance to cracking, deformation, and other forms of damage under pressure. ERA's CPVC pipe fittings, while functional, do not benefit from the same level of precision and surface smoothness control, which can lead to a reduced lifespan and lower performance under harsh conditions. Over time, the imperfections in ERA's fittings can contribute to failures in the piping system, ultimately leading to higher maintenance costs and potential system downtime.

Conclusion: The Superiority of IFAN's Precision Molding Technology

In the competitive market of CPVC pipe fittings, precision injection molding and surface smoothness control are critical factors in ensuring the quality, performance, and longevity of the product. IFAN's advanced molding techniques, including optimized material flow and stringent surface smoothness control, result in superior CPVC pipe fittings that offer enhanced durability, better fluid flow efficiency, and longer service life. In comparison, ERA's less precise molding process leads to inconsistencies in product quality, rougher surfaces, and a higher risk of performance issues. When it comes to ensuring reliable, high-performance CPVC pipe fittings, IFAN stands out as the clear leader in the industry.

IFAN PVC Pipe Fittings: Meeting Extensive International Standards for Optimal Performance

IFAN PVC pipe fittings not only adhere to the ASTM 2846 series standards but also support a broad range of other international and regional standards, including DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, and TIS 17-2532/1131-2535. This comprehensive compliance ensures that IFAN PVC pipe fittings meet the highest requirements for durability, reliability, and versatility, making them a top choice for various applications worldwide.

Hot Tags: cpvc plumbing pipe fitting, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, Brass Angle Valve, PPR Fitting Socket, PEX Brass Fitting, Pure PPR Fitting, Soap Dispenser, PPR Fitting Plug

Send Inquiry