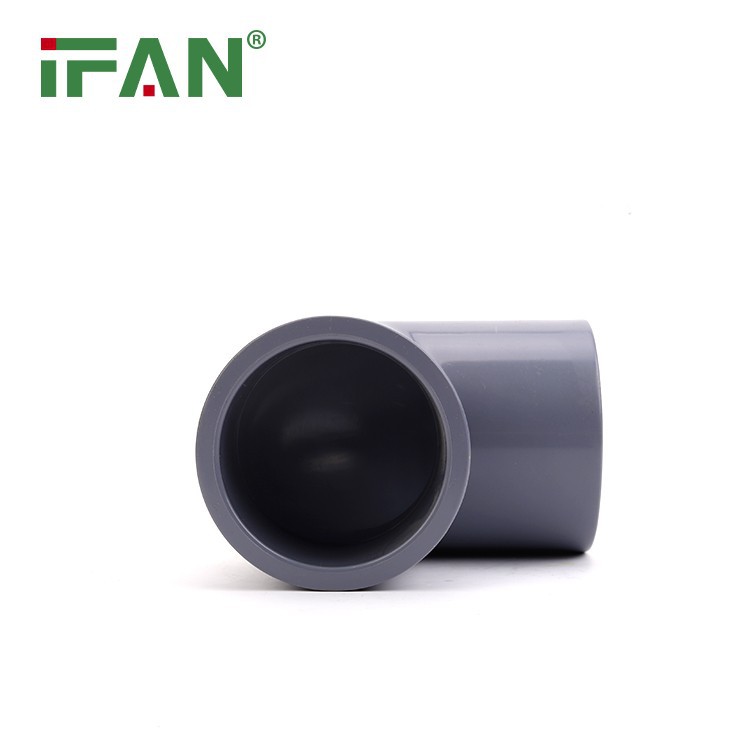

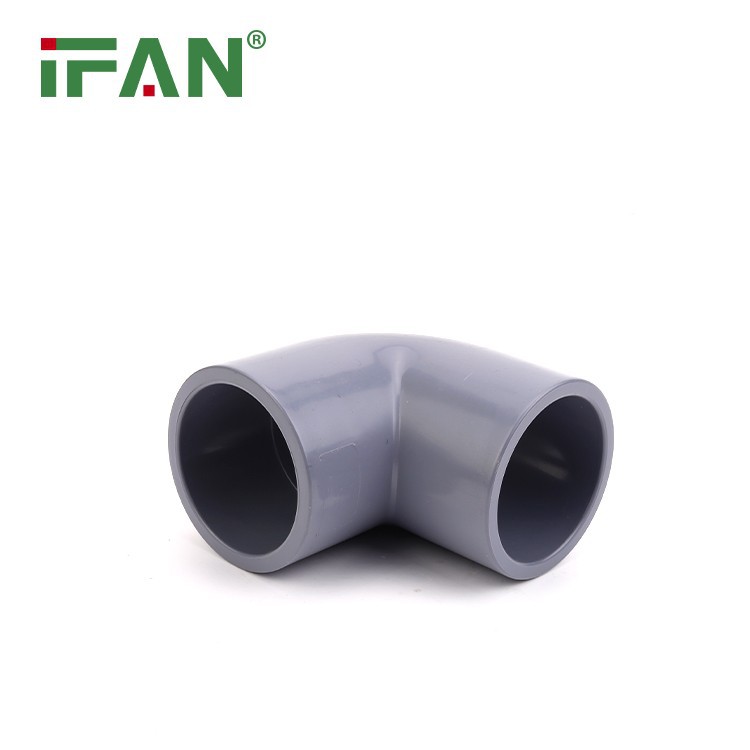

CPVC SCH80 Pipe Fitting Elbow

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN's product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

Bending Performance and Ease of Installation of CPVC Pipe Fittings

Introduction

Chlorinated Polyvinyl Chloride (CPVC) pipe fittings are extensively used in various plumbing and industrial applications due to their excellent mechanical properties, chemical resistance, and thermal stability. This article explores the bending performance and ease of installation of CPVC pipe fittings, highlighting their advantages, challenges, and best practices for achieving optimal results.

Bending Performance of CPVC Pipe Fittings

1. Material Flexibility: CPVC pipe fittings are designed to be robust yet flexible enough to accommodate minor bends and adjustments. This flexibility is a crucial factor that enhances their performance in dynamic environments where slight movements and vibrations are common.

2. Impact Resistance: CPVC pipes have high impact resistance, allowing them to withstand bending stresses without cracking or breaking. This property is especially important during installation and in applications where pipes may be subjected to physical impacts.

3. Thermal Bending: CPVC pipes can be bent using controlled heating methods. By applying heat evenly, the pipes become pliable and can be shaped to fit specific configurations. This method requires precise temperature control to avoid overheating, which could degrade the material.

4. Bend Radius and Limits: There are specific guidelines for the minimum bend radius of CPVC pipes to prevent undue stress and potential failure. Following these guidelines ensures that the pipes maintain their structural integrity and perform reliably over their service life.

Ease of Installation

1. Lightweight and Easy Handling: One of the significant advantages of CPVC pipe fittings is their lightweight nature. This makes them easy to handle and transport, reducing the labor and effort required during installation.

2. Simple Jointing Techniques: CPVC pipe fittings use solvent cement welding for joints, a straightforward and efficient method. This technique involves applying a solvent cement that chemically fuses the pipe and fitting, creating a strong, leak-proof bond.

3. Minimal Equipment Requirement: Installing CPVC pipes requires minimal equipment compared to metal piping systems. Basic tools such as pipe cutters, deburring tools, and applicators for solvent cement are generally sufficient for most installations.

4. Versatility in Installation: CPVC pipes and fittings can be installed in various orientations and configurations, including horizontal, vertical, and angled layouts. This versatility allows for customized piping solutions tailored to specific project requirements.

Challenges and Solutions

1. Thermal Expansion and Contraction: CPVC pipes expand and contract with temperature changes. Without proper accommodation, this can lead to joint stress and potential leaks. Implementing expansion loops or joints can mitigate this issue by providing flexibility within the system.

2. Solvent Cement Curing: The curing time for solvent cement is crucial for ensuring strong joints. Inadequate curing can result in weak bonds and potential leaks. Following manufacturer guidelines for curing times and environmental conditions ensures reliable joint integrity.

3. Bending Limitations: While CPVC pipes offer some flexibility, excessive bending can lead to stress and potential failure. Adhering to recommended bend radius guidelines and using proper bending techniques prevents undue stress on the pipes.

4. Environmental Factors: Exposure to UV light can degrade CPVC material over time. Protecting CPVC pipes from direct sunlight or using UV-resistant coatings extends their lifespan, especially in outdoor installations.

Best Practices for Installation

1. Proper Pipe Cutting and Preparation: Ensuring clean, square cuts on CPVC pipes is essential for creating strong joints. Deburring the edges and removing any burrs or debris enhances the effectiveness of solvent cement welding.

2. Uniform Application of Solvent Cement: Applying solvent cement evenly on both the pipe and fitting surfaces ensures a strong bond. Excess cement should be avoided, as it can weaken the joint and lead to leaks.

3. Adequate Support and Clamping: Providing adequate support and clamping during installation prevents sagging and stress on the joints. Supports should be placed at regular intervals to distribute the load evenly and maintain alignment.

4. Compliance with Codes and Standards: Following industry codes and standards for CPVC pipe installations ensures safety, reliability, and compliance with regulatory requirements. These standards provide guidelines for proper installation practices and material specifications.

Applications and Case Studies

1. Residential Plumbing: CPVC pipe fittings are widely used in residential plumbing for both hot and cold water distribution. Their ease of installation, combined with their resistance to corrosion and scale build-up, makes them ideal for domestic use.

2. Industrial Applications: In industrial settings, CPVC pipes are used for transporting various chemicals and fluids due to their chemical resistance. Case studies have demonstrated their reliability in harsh environments, including chemical processing plants and wastewater treatment facilities.

3. Fire Sprinkler Systems: CPVC pipes are approved for use in fire sprinkler systems. Their high heat resistance and ease of installation make them a preferred choice for fire protection applications in commercial and residential buildings.

Conclusion

CPVC pipe fittings offer excellent bending performance and ease of installation, making them suitable for a wide range of applications. Their flexibility, impact resistance, and straightforward jointing techniques contribute to their popularity in plumbing and industrial systems. By addressing challenges through proper installation practices and adherence to guidelines, CPVC pipes can provide reliable, long-lasting service. Their successful use in various case studies underscores their versatility and effectiveness, reinforcing their position as a preferred material for modern piping systems.

Hot Tags: cpvc sch80 pipe fitting elbow, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, Sanitary Product, PEX Brass Fitting, Hose, PEX AL PEX Pipe Laser, PPR Fitting Female Tee, PEX Sliding Fitting

Send Inquiry