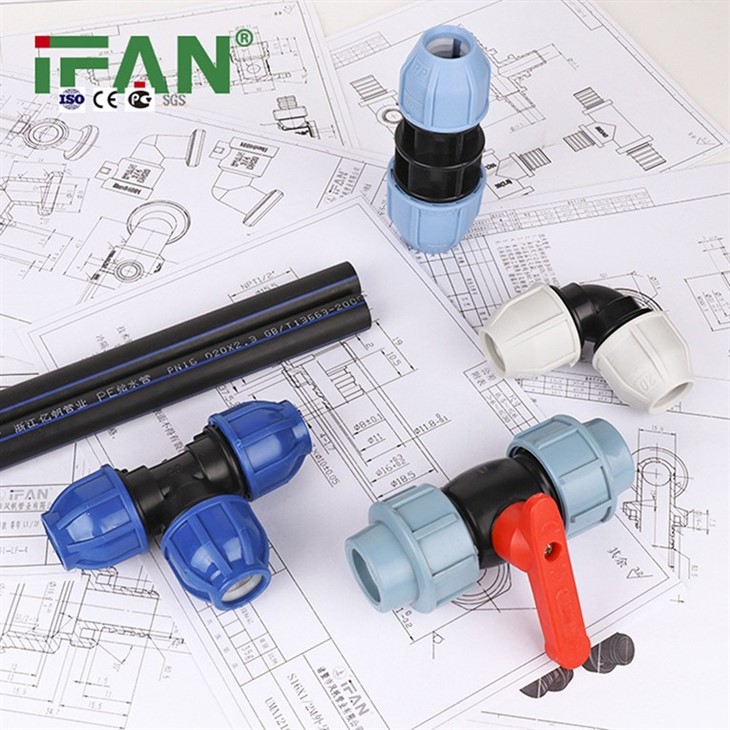

Free Sample Blue HDPE Pipe Fittings

Material: PE

Size: 20-110MM

Color: Blue

Brand: IFAN

Sample: Free

Emergency Maintenance and Replacement Methods for HDPE Pipe Fittings

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN's product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

Introduction

High-Density Polyethylene (HDPE) pipe fittings are essential components of various infrastructure systems, and in the event of emergencies such as leaks or damages, prompt and effective maintenance or replacement procedures are crucial. This article will outline the methods for emergency maintenance and replacement of HDPE pipe fittings, ensuring the integrity and functionality of the overall system.

Assessment and Inspection

In the event of a potential issue with HDPE pipe fittings, the first step is to conduct a thorough assessment and inspection of the affected area. This involves identifying the extent of the damage, determining the cause of the problem, and evaluating the overall condition of the fittings. Visual inspections, pressure tests, and non-destructive evaluation techniques can be employed to assess the integrity of the fittings and determine the appropriate course of action for maintenance or replacement.

Temporary Repairs and Containment

For immediate response to emergencies involving HDPE pipe fittings, temporary repair measures may be necessary to contain leaks or mitigate damages. Techniques such as clamping, sealing, or using temporary patching materials can help minimize the impact of the issue while more comprehensive maintenance or replacement procedures are being planned and executed. Temporary repairs should be performed with safety and environmental considerations in mind, and they should not compromise the long-term integrity of the system.

Fusion Welding and Joint Repair

In instances where HDPE pipe fittings require repair or replacement, fusion welding techniques play a critical role. Fusion welding allows for the seamless joining of HDPE pipes and fittings, ensuring leak-free and durable connections. In the case of joint failures or damages, specialized fusion welding equipment and trained personnel can facilitate the repair of HDPE joints, restoring the integrity of the pipeline system. Proper surface preparation, heating, and cooling procedures are essential for successful fusion welding and joint repair.

Replacement Procedures and Compatibility

When emergency situations necessitate the replacement of HDPE pipe fittings, careful consideration of compatibility and specifications is imperative. Replacement fittings should meet the required standards, dimensions, and material properties to ensure optimal performance and compatibility with the existing system. Additionally, proper installation techniques, including fusion welding and joint assembly, must be followed to guarantee the reliability and longevity of the replaced fittings within the infrastructure.

Preventative Maintenance and Contingency Planning

To minimize the occurrence of emergency situations involving HDPE pipe fittings, proactive maintenance and contingency planning are essential. Regular inspections, testing, and monitoring of HDPE fittings can help identify potential issues before they escalate into emergencies, allowing for timely interventions and preventive maintenance measures. Furthermore, developing contingency plans and establishing protocols for rapid response to emergencies can help mitigate the impact of unexpected events, ensuring the resilience and reliability of the overall infrastructure.

Conclusion

In conclusion, emergency maintenance and replacement methods for HDPE pipe fittings involve assessment and inspection, temporary repairs, fusion welding and joint repair, replacement procedures and compatibility considerations, as well as preventative maintenance and contingency planning. By implementing these methods, infrastructure managers can effectively address emergencies, restore the functionality of HDPE pipe fittings, and maintain the integrity of the overall system, ultimately ensuring the safety, efficiency, and longevity of infrastructure networks.

Hot Tags: free sample blue hdpe pipe fittings, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, PPR Fitting Female Seated Elbow, PPR Fitting Male Socket, PPR Fitting Female Union, Glass Fiber PPR Pipe, PPR Fitting Male Union, PEXB Floor Heating PEX Pipe

Send Inquiry