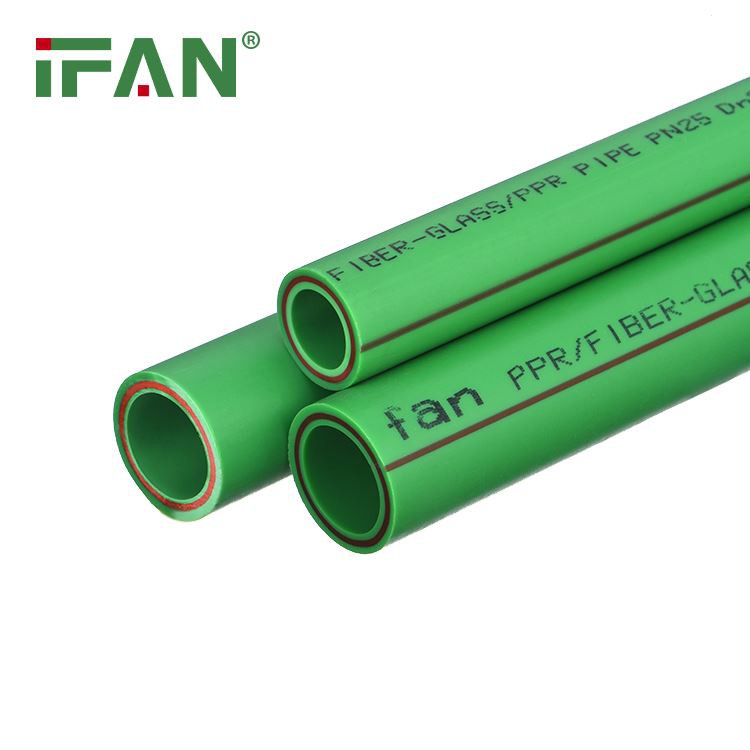

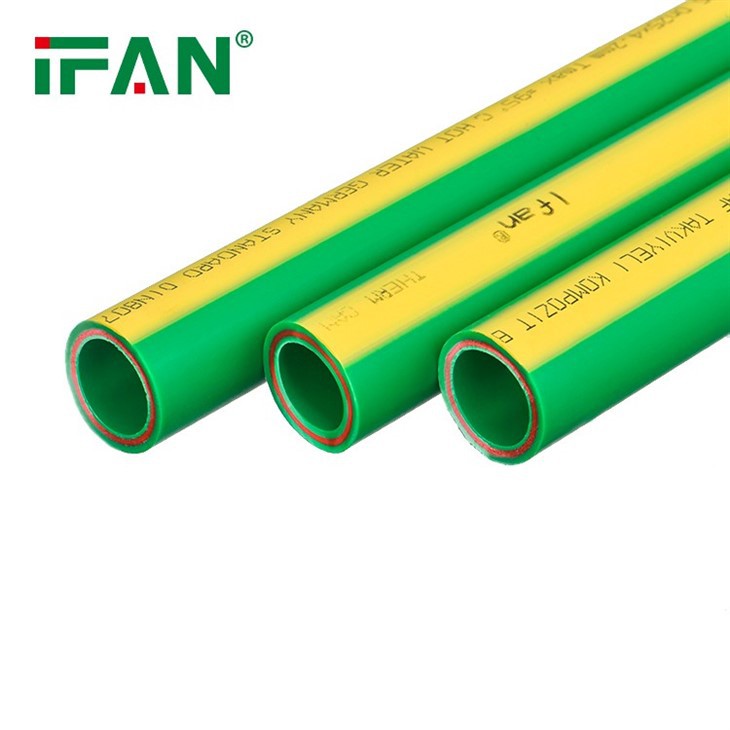

Green Color PPR Pipe

Fluid Transport Characteristics and Hydraulic Performance of PPR Plastic Pipes

Introduction:

PPR (Random Copolymer Polypropylene) plastic pipes are widely used in various industries due to their outstanding properties. In this article, we will discuss the fluid transport characteristics and hydraulic performance of PPR plastic pipes, with a focus on their importance in different applications.

1. Understanding Fluid Transport Characteristics:

1.1 Definition: Fluid transport characteristics refer to the behavior of fluids flowing through PPR plastic pipes, including flow rate, pressure drop, and resistance to flow.

1.2 Significance: Understanding the fluid transport characteristics is crucial for designing efficient piping systems and ensuring optimal fluid flow.

1.3 Mechanism: PPR plastic pipes have a smooth inner surface, which reduces frictional losses and provides excellent fluid flow characteristics. The material's low roughness coefficient contributes to minimal pressure drop during fluid transportation.

2. Hydraulic Performance of PPR Plastic Pipes:

2.1 High Flow Capacity: PPR plastic pipes offer high flow capacity due to their smooth interior surface, allowing for efficient fluid transport with minimal pressure loss.

2.2 Low Friction Losses: The smooth inner surface of PPR plastic pipes reduces friction losses, resulting in lower energy consumption and improved hydraulic efficiency.

2.3 Resistance to Scaling and Corrosion: PPR plastic pipes are resistant to scaling and corrosion, ensuring long-term hydraulic performance and minimizing maintenance requirements.

2.4 Excellent Thermal Insulation: PPR plastic pipes have low thermal conductivity, reducing heat loss during fluid transportation and maintaining the desired temperature of the conveyed fluid.

3. Applications and Examples:

3.1 Plumbing Systems: PPR plastic pipes are commonly used in residential and commercial plumbing systems for water supply and distribution. Their high flow capacity and resistance to scaling make them ideal for delivering clean and potable water.

3.2 Heating and Cooling Systems: PPR plastic pipes are suitable for radiant floor heating and cooling systems. Their excellent thermal insulation properties ensure efficient heat transfer and temperature control.

3.3 Industrial Applications: PPR plastic pipes find applications in various industrial sectors, such as chemical processing, pharmaceuticals, and food processing. They provide reliable fluid transport with resistance to corrosion and scaling.

4. Quality Standards and Certifications:

4.1 Compliance with International Standards: PPR plastic pipes should meet relevant international standards, such as ISO 15874, DIN 8077/8078, and ASTM F2389, to ensure their quality and performance.

4.2 Certification: PPR plastic pipes may be certified by recognized certification bodies, such as NSF International or WRAS (Water Regulations Advisory Scheme), indicating their compliance with specific industry requirements.

Conclusion:

PPR plastic pipes exhibit excellent fluid transport characteristics and hydraulic performance, making them suitable for a wide range of applications. Their high flow capacity, low friction losses, resistance to scaling and corrosion, and thermal insulation properties contribute to efficient fluid transportation and system longevity. Whether used in plumbing, heating, cooling, or industrial applications, PPR plastic pipes provide reliable and sustainable solutions for fluid conveyance.

Hot Tags: green color ppr pipe, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, White Plastic PPR Pipe, Plastic PPR Pipe, Water Plastic PPR Pipe, Grey Plastic PPR Pipe, PPR Pipe, Green Plastic PPR Pipe

Send Inquiry