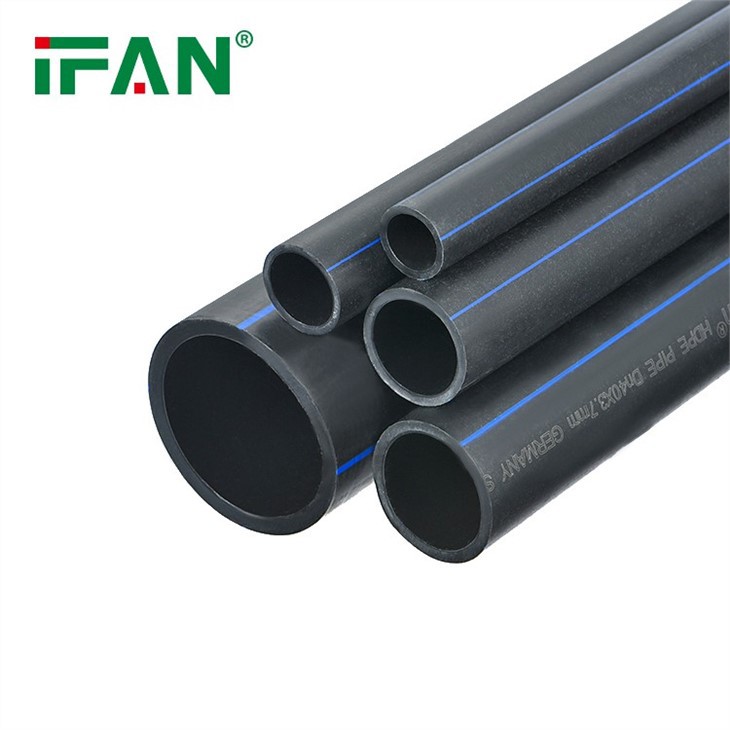

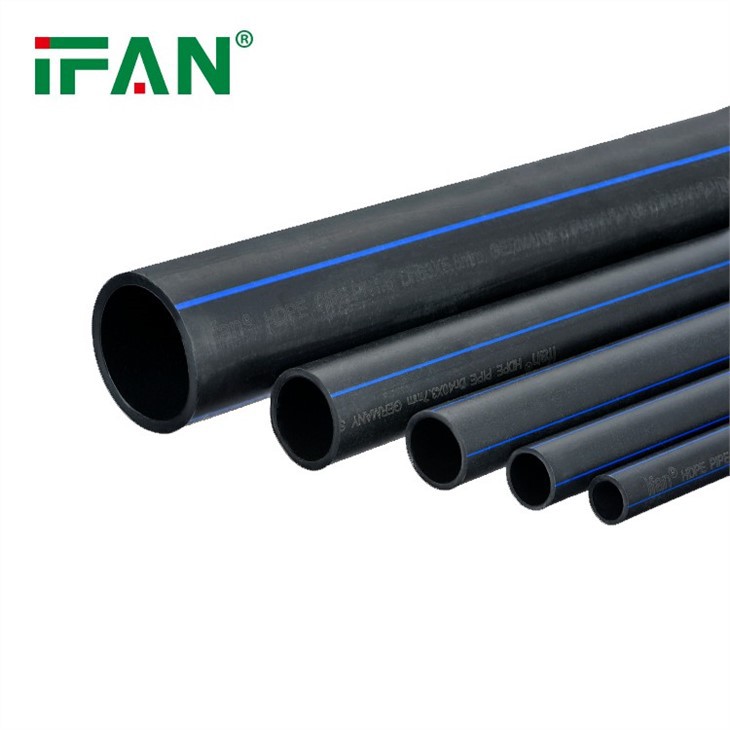

Manufacturing Of HDPE Pipes

The production of HDPE pipes involves various manufacturing processes, including extrusion, injection molding, and other methods. Extrusion is one of the most widely used methods for manufacturing HDPE pipes. It involves heating and melting the raw material, HDPE granules, and passing it through an extrusion machine. The machine has a die that shapes the melted material into a long pipe. The pipe is then cooled using a water bath before being cut to the required length. One of the advantages of extrusion is that the process can be used to create pipes of different diameters and lengths, making it a versatile process for producing HDPE pipes.

Injection molding is another common process used for manufacturing HDPE pipes. During the process, the HDPE material is melted in a hopper and then injected into a mold cavity. The mold is then cooled, and the solidified plastic pipe is ejected from the mold. This process is ideal for producing small-diameter pipes with complex shapes.

In addition to extrusion and injection molding, other methods can be used to produce HDPE pipes, such as rotational molding, blow molding, and compression molding. Rotational molding involves heating and melting the HDPE material and then rotating the mold to distribute the melted material evenly inside it. Blow molding involves melting the HDPE material and then blowing it into a mold to form a hollow pipe. Compression molding involves placing the HDPE material in a mold and then applying pressure to compress it into shape.

Overall, HDPE pipes are produced using a wide range of manufacturing methods, depending on the specific requirements and application for the pipes. Regardless of the process used, the end result is a high-quality pipe that offers exceptional durability, corrosion resistance, and flexibility.

Hot Tags: manufacturing of hdpe pipes, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample,

Send Inquiry