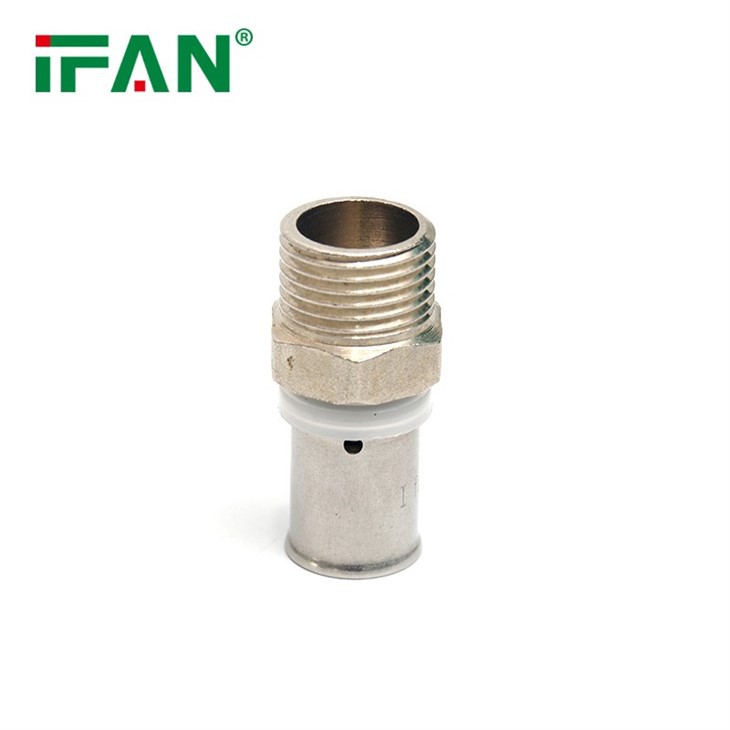

PALCONN Brass Press Fitting

Title: Corrosion Protection and Material Selection for PEX Pressure Fittings

Introduction:

PEX (cross-linked polyethylene) pressure fittings are widely used in plumbing systems due to their durability, flexibility, and ease of installation. However, it is essential to consider corrosion protection and material selection to ensure the longevity and performance of PEX fittings. In this article, we will discuss various corrosion protection methods and explore the factors involved in choosing the right materials for PEX pressure fittings.

1. Corrosion Protection Methods:

a. Internal Coatings: Applying internal coatings to PEX pressure fittings can protect them from corrosion caused by aggressive water or chemicals. These coatings act as a barrier between the fitting's surface and the corrosive environment, preventing direct contact and reducing the risk of deterioration.

b. Cathodic Protection: Cathodic protection is commonly used to protect metallic components in a plumbing system. By connecting sacrificial anodes made of more reactive metals (such as zinc or magnesium) to the PEX fittings, the anodes corrode instead, protecting the fittings from potential damage.

c. Insulation: Insulating PEX pressure fittings can minimize the risk of corrosion caused by condensation or temperature differentials. Proper insulation helps maintain a consistent temperature and prevents the formation of moisture, reducing the likelihood of corrosion.

2. Material Selection for PEX Pressure Fittings:

a. PEX Grades: PEX pressure fittings are available in different grades, including PEX-A, PEX-B, and PEX-C. Each grade has varying resistance to corrosion, with PEX-A generally being the most resistant. Choosing a higher-grade PEX material can enhance the fittings' corrosion resistance and overall durability.

b. Brass and Copper Alloys: Brass and copper alloy fittings are commonly used in combination with PEX pipes. These materials exhibit excellent corrosion resistance, making them suitable for various plumbing applications. However, compatibility with PEX materials and water chemistry should be considered to avoid any potential galvanic corrosion issues.

c. Stainless Steel: Stainless steel fittings offer exceptional corrosion resistance, making them an ideal choice for corrosive environments or applications that require high durability. Stainless steel fittings are often used in commercial or industrial plumbing systems where corrosion protection is crucial.

3. Water Chemistry Considerations:

The water chemistry in a plumbing system can significantly impact the corrosion potential of PEX pressure fittings. Factors such as pH levels, dissolved oxygen, chlorides, and other contaminants can accelerate corrosion. Conducting water tests and consulting with experts can help determine the ideal material selection and corrosion protection methods based on the specific water chemistry.

4. Maintenance and Inspection:

Regular maintenance and inspection are essential to ensure the effectiveness of corrosion protection measures for PEX pressure fittings. Inspecting fittings for signs of corrosion, leaks, or degradation can help identify any issues promptly. It is recommended to follow manufacturer guidelines for maintenance procedures, including periodic cleaning, reapplication of coatings, or replacing sacrificial anodes if necessary.

5. Compliance with Standards and Regulations:

When selecting materials and implementing corrosion protection measures for PEX pressure fittings, it is crucial to comply with relevant industry standards and regulations. These standards provide guidelines for material performance, compatibility, and corrosion resistance, ensuring the safety and reliability of the plumbing system.

Conclusion:

Proper corrosion protection and material selection are essential for maximizing the lifespan and performance of PEX pressure fittings. By considering various corrosion protection methods, selecting appropriate materials, understanding water chemistry considerations, conducting regular maintenance and inspections, and complying with industry standards, the risk of corrosion-related issues can be minimized, ensuring a durable and reliable plumbing system.

Hot Tags: palconn brass press fitting, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample,

Send Inquiry