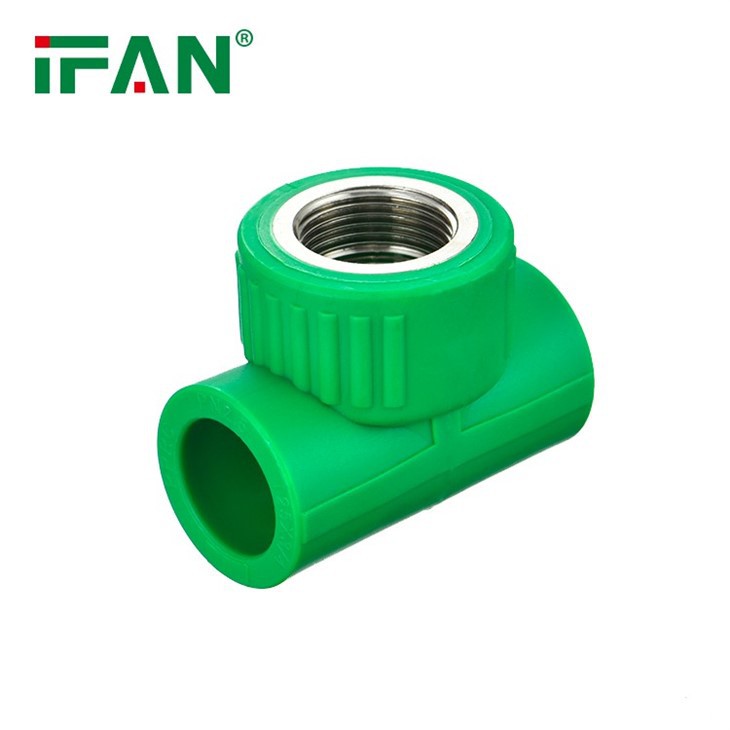

PPR Female Tee Fitting

Testing of Grip Strength and Anti-Slipping Performance of PPR Pipe Fittings

Introduction:

The grip strength and anti-slipping performance of PPR pipe fittings are critical factors in ensuring the reliability and safety of plumbing installations. Properly assessing these properties through rigorous testing procedures is essential to guarantee the secure and long-lasting connection of PPR pipe fittings in plumbing systems. This article aims to provide a comprehensive analysis of the testing methods, significance, factors influencing these properties, and their relevance in different applications.

1. Importance of Grip Strength and Anti-Slipping Performance:

Grip strength refers to the ability of PPR pipe fittings to maintain a secure and tight connection under internal and external forces, including pressure, temperature variations, and mechanical stress. Anti-slipping performance relates to the resistance of the fittings to unintentional disconnection or movement once installed. Both properties are crucial for preventing leaks, ensuring system integrity, and minimizing maintenance requirements.

2. Testing Methods for Grip Strength:

The grip strength of PPR pipe fittings is typically evaluated through standardized tests that simulate real-world installation conditions. These tests involve applying specified loads or pressures to the fittings while measuring the resulting deformation, displacement, or leakage. For example, hydrostatic pressure tests assess the fittings' ability to withstand internal pressure, while mechanical loading tests evaluate their resistance to external forces and impacts.

3. Factors Affecting Grip Strength:

Several factors can influence the grip strength of PPR pipe fittings, including the design of the fittings, the quality of the jointing method (e.g., fusion welding), and the compatibility of the fittings with pipes and other components. The material properties, surface roughness, and geometric features of the fittings also play a significant role in determining their grip strength. Proper fusion welding parameters and installation techniques are essential for achieving optimal grip performance.

4. Testing Methods for Anti-Slipping Performance:

The anti-slipping performance of PPR pipe fittings is assessed through tests that replicate the conditions leading to unintended disconnection or movement. These tests may involve applying torsional or tensile forces to the assembled fittings, simulating potential stresses during operation. Additionally, environmental tests under varying temperatures and moisture levels can evaluate the fittings' resistance to slipping under challenging conditions.

5. Factors Affecting Anti-Slipping Performance:

The anti-slipping performance of PPR pipe fittings depends on factors such as the surface texture, interfacial friction, and the effectiveness of the jointing method. Proper surface treatment and the use of compatible sealants or adhesives can improve the anti-slipping characteristics of the fittings. Moreover, adherence to installation guidelines and standards is crucial for minimizing the risk of unintended slippage in practical applications.

6. Applications and Relevance:

Grip strength and anti-slipping performance are particularly important for PPR pipe fittings used in pressurized water supply, heating, and cooling systems. In applications where consistent flow and pressure are essential, such as in industrial or residential plumbing, reliable grip strength and anti-slipping characteristics are indispensable. By rigorously testing and selecting PPR pipe fittings with superior grip performance, engineers can ensure the integrity and longevity of the entire piping system.

Conclusion:

Testing the grip strength and anti-slipping performance of PPR pipe fittings is essential for evaluating their reliability and functionality in plumbing applications. By considering the factors that influence these properties and conducting thorough tests, manufacturers and engineers can ensure the fittings' suitability for specific installations. Prioritizing grip strength and anti-slipping performance contributes to the overall safety, efficiency, and durability of PPR pipe fittings in various plumbing systems.

Hot Tags: ppr female tee fitting, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, PPR Fitting Female Tee, PPR Fitting Female Elbow, PPR Fitting Female Socket, PPR Fitting Male, PPR Fitting Female Seated Elbow, PPR Fitting Female Union

Send Inquiry