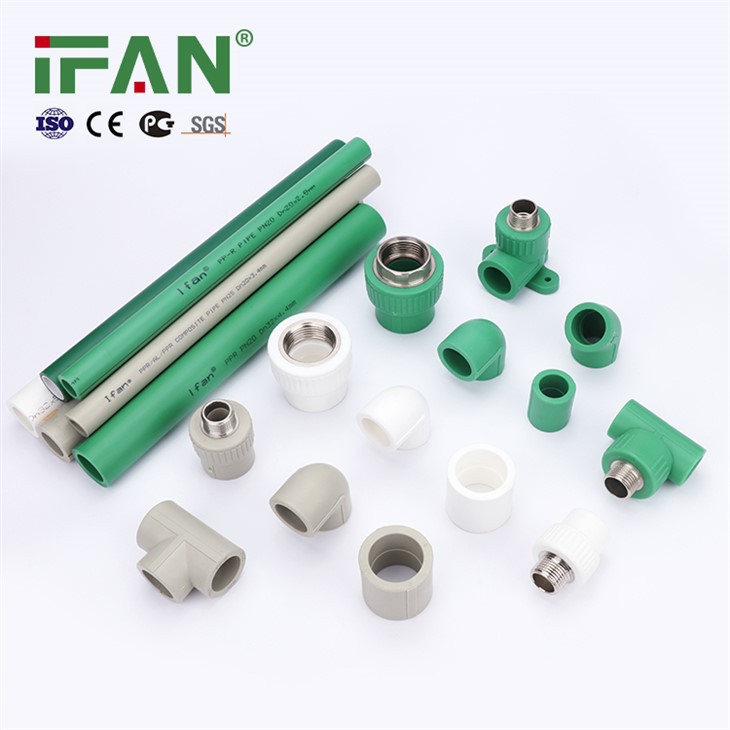

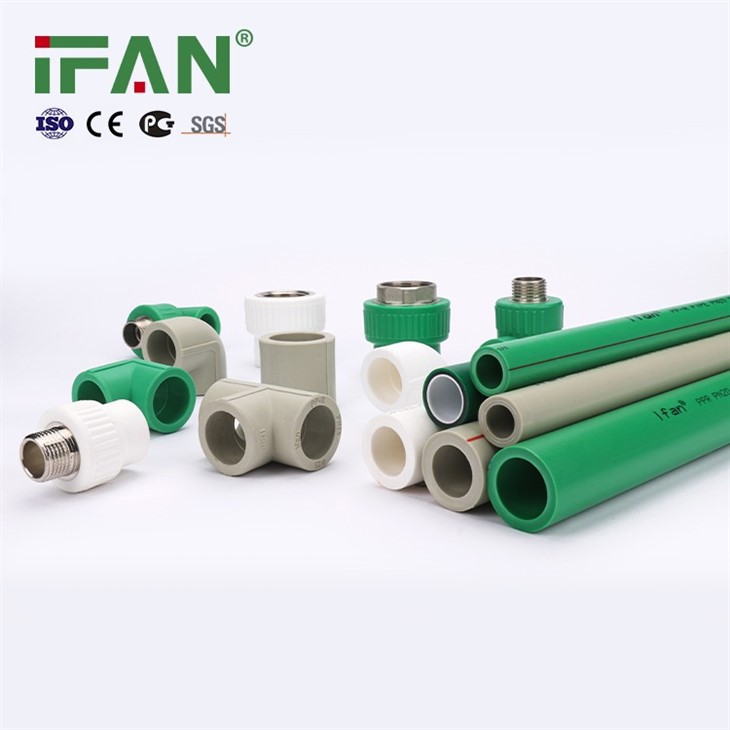

PPR Pipe And Fitting

Comparative Analysis of PPR Pipes and Other Piping Materials

Introduction:

When it comes to selecting the right piping material for various applications, it is crucial to understand the comparisons and differences between different options. In this article, we will conduct a comprehensive comparative analysis of PPR (Polypropylene Random Copolymer) pipes with other commonly used piping materials, highlighting their key characteristics and advantages.

1. Material Composition and Properties:

PPR Pipes: PPR pipes are made of polypropylene, which offers excellent chemical resistance, high tensile strength, and moderate flexibility. They are known for their durability, non-toxicity, and resistance to corrosion and scale.

Other Piping Materials: Other commonly used piping materials include PVC (Polyvinyl Chloride), CPVC (Chlorinated Polyvinyl Chloride), copper, and stainless steel. Each material has its unique properties, such as flexibility, heat resistance, or conductivity, which are suitable for specific applications.

2. Installation and Joining Methods:

PPR Pipes: PPR pipes are joined using a heat fusion technique called socket fusion, where the pipe and fitting are heated and fused together without the need for additional adhesives or solvents. This method ensures leak-proof connections and convenient installation.

Other Piping Materials: PVC pipes are typically joined using solvent cement, while CPVC pipes require a special adhesive. Copper pipes often use soldering or compression fittings, whereas stainless steel pipes are commonly welded or threaded together. These joining methods may require additional tools, expertise, and time for installation.

3. Chemical Resistance and Corrosion Protection:

PPR Pipes: PPR pipes exhibit excellent chemical resistance, making them suitable for various applications involving aggressive chemicals. They are resistant to corrosion, scale buildup, and chemical degradation, ensuring a long lifespan and reliable performance.

Other Piping Materials: PVC and CPVC pipes are also resistant to many chemicals; however, they may not be suitable for extremely high-temperature or highly corrosive environments. Copper pipes are susceptible to corrosion from certain acidic or alkaline substances, while stainless steel pipes offer good corrosion resistance in most applications.

4. Thermal Conductivity and Insulation:

PPR Pipes: PPR pipes have low thermal conductivity, which minimizes heat loss or gain during fluid transportation. This helps maintain the desired temperature of the conveyed material and contributes to energy efficiency.

Other Piping Materials: PVC and CPVC pipes have relatively higher thermal conductivity compared to PPR pipes, which may result in more significant heat transfer. Copper pipes have excellent thermal conductivity, making them suitable for applications that require efficient heat transfer. Stainless steel pipes have moderate thermal conductivity and provide better insulation than metal pipes.

5. Cost Considerations:

PPR Pipes: PPR pipes are generally cost-effective due to their affordable material and installation costs. They require less workforce, time, and additional accessories for installation, reducing overall project expenses.

Other Piping Materials: The cost of other piping materials varies depending on factors such as material type, size, and installation requirements. PVC and CPVC pipes are often considered budget-friendly options, while copper and stainless steel pipes tend to be more expensive.

Conclusion:

PPR pipes offer several advantages over other piping materials. They provide excellent chemical resistance, durability, ease of installation, and cost-effectiveness. However, the choice of piping material ultimately depends on specific application requirements, such as temperature, pressure, chemical compatibility, and budget. A thorough analysis of these factors will help determine the most suitable piping material for each application.

Hot Tags: ppr pipe and fitting, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, Pure Plastic PPR Pipe, PPR Pipe, Grey Plastic PPR Pipe, Plastic PPR Pipe, White Plastic PPR Pipe, Water Plastic PPR Pipe

Send Inquiry