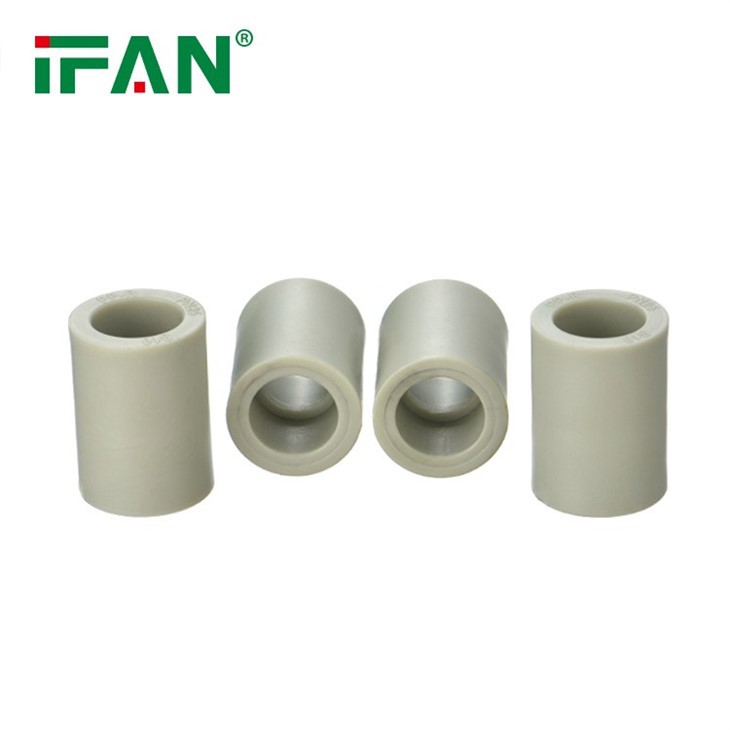

PPR Plastic Socket Fitting

Title: Impact Resistance and Influence of Temperature Variations on PPR Pipe Fittings

Introduction:

The impact resistance and ability to withstand temperature variations are crucial factors in evaluating the durability and reliability of PPR pipe fittings. Assessing these properties through comprehensive testing methods is essential for ensuring the long-term performance and safety of plumbing systems. This article aims to provide a detailed analysis of the testing procedures, significance, factors affecting these properties, and their relevance in different applications.

1. Importance of Impact Resistance and Temperature Variation:

Impact resistance refers to the ability of PPR pipe fittings to withstand sudden forces or impacts without cracking, breaking, or experiencing significant deformation. Temperature variation resistance relates to the fittings' ability to maintain their structural integrity and functionality under extreme temperature fluctuations. Both properties are critical for ensuring the longevity and reliability of PPR pipe fittings in real-world applications.

2. Testing Methods for Impact Resistance:

The impact resistance of PPR pipe fittings is typically evaluated through standardized tests that simulate potential impacts during installation, operation, or maintenance. These tests involve subjecting the fittings to controlled impacts, such as drop tests, pendulum impact tests, or dynamic loading tests. The fittings' performance is assessed based on criteria such as crack formation, deformation, or leakage after the impact.

3. Factors Affecting Impact Resistance:

Several factors can influence the impact resistance of PPR pipe fittings, including the quality and composition of the PPR material, the manufacturing process, and the design of the fittings. Material modifications, such as incorporating impact modifiers or reinforcing agents, can enhance the fittings' resistance to impact forces. Additionally, proper installation techniques and support structures can minimize the risk of damage from external impacts.

4. Influence of Temperature Variations:

Temperature variations can have a significant impact on the performance of PPR pipe fittings. PPR materials exhibit excellent dimensional stability and resistance to thermal stress, making them suitable for a wide temperature range. However, extreme temperature variations can lead to thermal expansion or contraction, potentially affecting the fittings' sealing and mechanical properties. Testing the fittings under different temperature conditions helps assess their ability to withstand such variations.

5. Testing Methods for Temperature Variation Influence:

The influence of temperature variations on PPR pipe fittings is typically evaluated through thermal cycling tests or exposure to extreme temperatures. These tests subject the fittings to repeated cycles of hot and cold water or exposure to high and low-temperature environments. The fittings' dimensional changes, mechanical properties, and sealing performance are assessed before and after the tests to evaluate any potential adverse effects.

6. Applications and Relevance:

The impact resistance and ability to withstand temperature variations are crucial for PPR pipe fittings used in various plumbing systems, including water supply, heating, and cooling applications. In regions with extreme temperature variations or where impacts during installation or maintenance are likely, these properties become even more critical. Selecting PPR pipe fittings with excellent impact resistance and temperature variation resilience ensures the longevity and reliability of the entire plumbing system.

Conclusion:

Testing the impact resistance and the influence of temperature variations on PPR pipe fittings is essential for evaluating their durability and performance in plumbing applications. By considering the factors that affect these properties and conducting appropriate testing, manufacturers and engineers can ensure the suitability of PPR fittings for specific installations. Prioritizing impact resistance and temperature variation resilience enhances the reliability, safety, and long-term functionality of PPR pipe fittings in diverse plumbing systems.

Hot Tags: ppr plastic socket fitting, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, PPR Fitting Elbow, Pure PPR Fitting, PPR Fitting Female, PPR Fitting Tee, PPR Fitting Socket, PPR Fitting Plug

Send Inquiry