Introduction:

Pneumatic conveying systems are widely used in various industries for the efficient and reliable transportation of bulk materials such as powders, granules, and pellets. The conveying of such materials is achieved by means of a network of pipes or tubes, through which fluids or air is passed, providing the motive force to transport the material from one location to another. The PPC tube, or positive pressure conveying tube, is a specialized type of tube used to convey solid materials under pressure. This article will discuss the features, advantages, and use cases of PPR tubes.

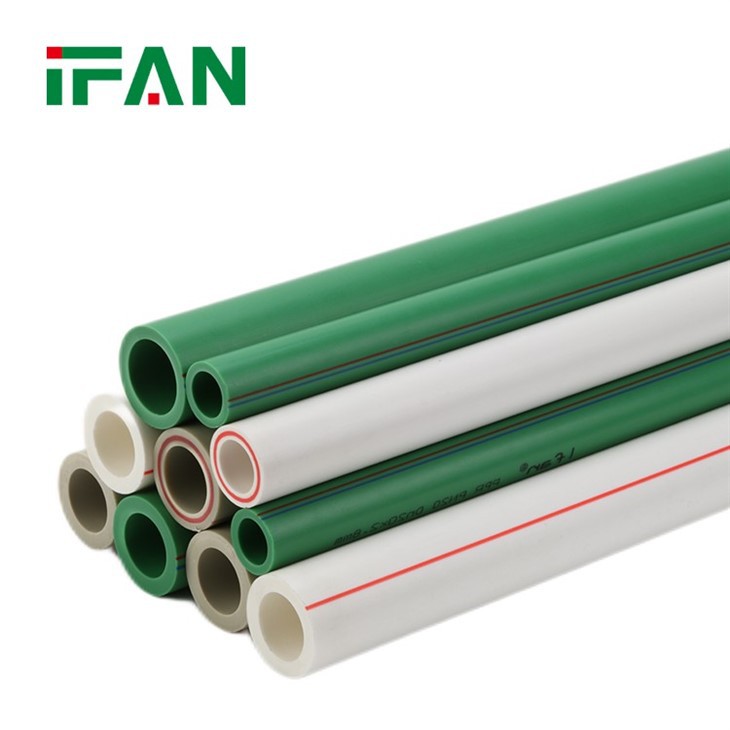

Features of PPR Tubes:

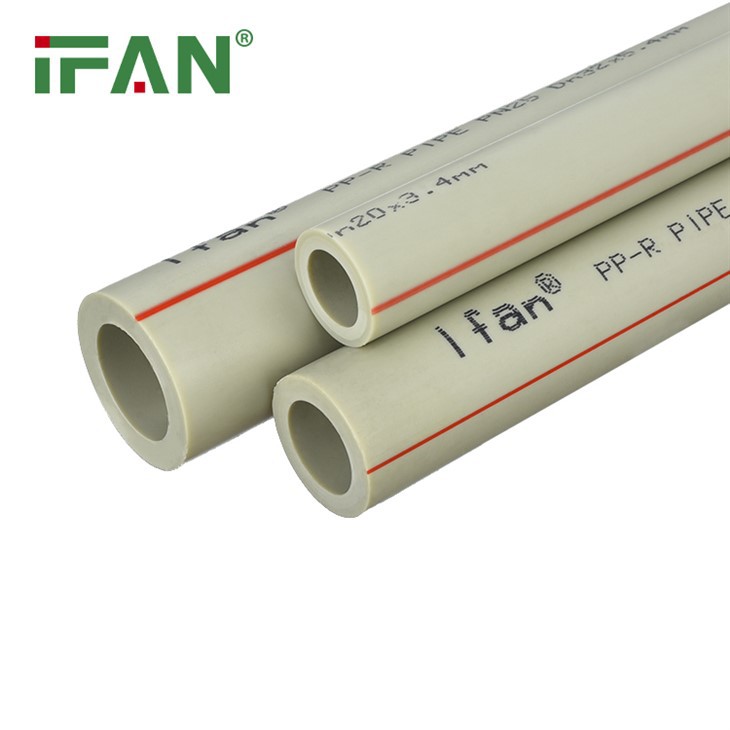

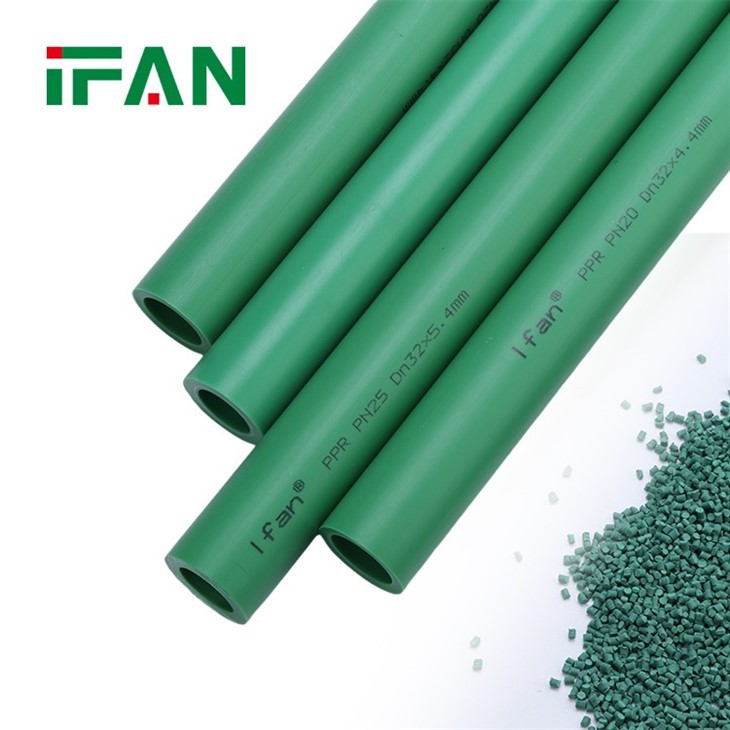

1. High Pressure Resistance– PPR tubes are designed for conveying solid materials under pressure. Hence they are made from high-quality materials that can withstand the pressure and stress of conveying. PPR tubes can handle pressure up to 6bar, and can handle high-temperature materials up to 110°C.

2. Durable and Corrosion-Resistant- PPR tubes are made from a special type of polypropylene that is highly durable and resistant to corrosion. They are not susceptible to chemical attack or aggressive substances like acids and bases, making them ideal for conveying materials in harsh environments.

3. Good Insulation Properties- PPR tubing has excellent insulation properties, which makes it highly resistant to heat and cold. This feature makes it ideal for use in extreme temperature environments.

4. Easy to Clean- PPR tubes have a smooth surface which makes them easy to clean, making them ideal for conveying food and pharmaceutical products where hygiene is crucial.

Advantages of PPR Tubes:

1. Energy Savings- PPR tubes use positive pressure to convey materials, which eliminates the need for an exhaust air system. This results in energy savings of up to 50% compared to other types of conveying systems.

2. Reduced Downtime- The special design of PPR tubes ensures that they are highly resistant to clogging and blockages. This makes it less likely for the system to fail, which reduces downtime and maintenance costs.

3. Cost-Effective- PPR tubes are lightweight, easy to install and maintain, and have a long service life. These features make them highly cost-effective in the long run.

4. Suitable for Various Applications- PPR tubes are versatile and can be used to convey a wide range of solid materials such as powders, granules, and pellets. They are used in various industries such as food processing, pharmaceuticals, plastics, and chemicals.

5. Flexible- PPR tubes can be bent and adjusted to fit into tight spaces and complex configurations, making them adaptable to different types of plants and conveying systems.

Use Cases of PPR Tubes:

1. Food Processing- PPR tubes are ideal for conveying food products like sugar, flour, and dairy products. They are highly resistant to clogging, easy to clean, and don't transfer any odors or flavors to the food products.

2. Pharmaceuticals- The high hygiene levels required in the pharmaceutical industry make PPR tubes an excellent choice for conveying sensitive drugs and medicines.

3. Chemicals- PPR tubes are ideal for conveying chemicals, as they are resistant to aggressive materials and corrosion.

4. Plastics- PPR tubes are used in the manufacturing of plastic products, as they can handle high-temperature materials up to 110°C, which is required in the plastics industry.

5. Agriculture- PPR tubes are used in the agriculture industry to convey granules such as fertilizer, seeds, and animal feed.

Conclusion:

PPR tubes are an excellent choice for conveying solid materials under pressure, with high pressure resistance and excellent corrosion and heat resistance. They offer energy savings, reduced downtime, flexibility, and versatility, making them suitable for a wide range of industrial applications. PPR tubes should be considered as an important component in an effective and efficient conveying system.

Hot Tags: ppr tube, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, Glass Fiber PPR Pipe, Aluminum PPR Pipe, PPR Fitting

Send Inquiry