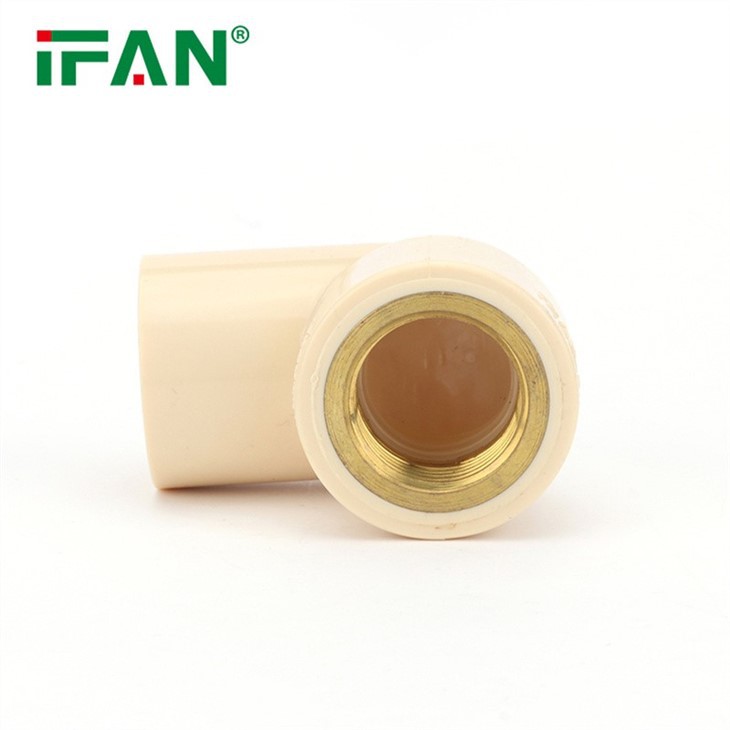

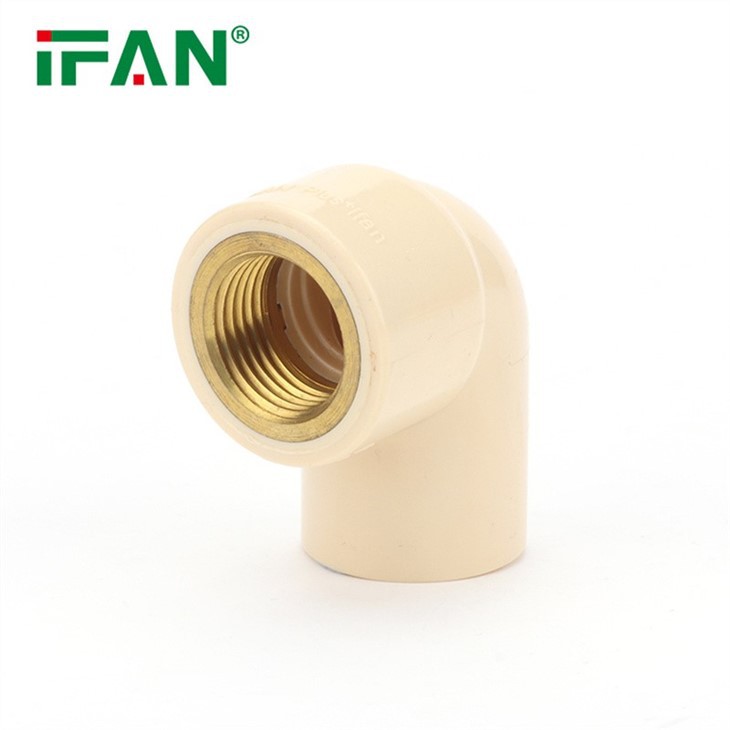

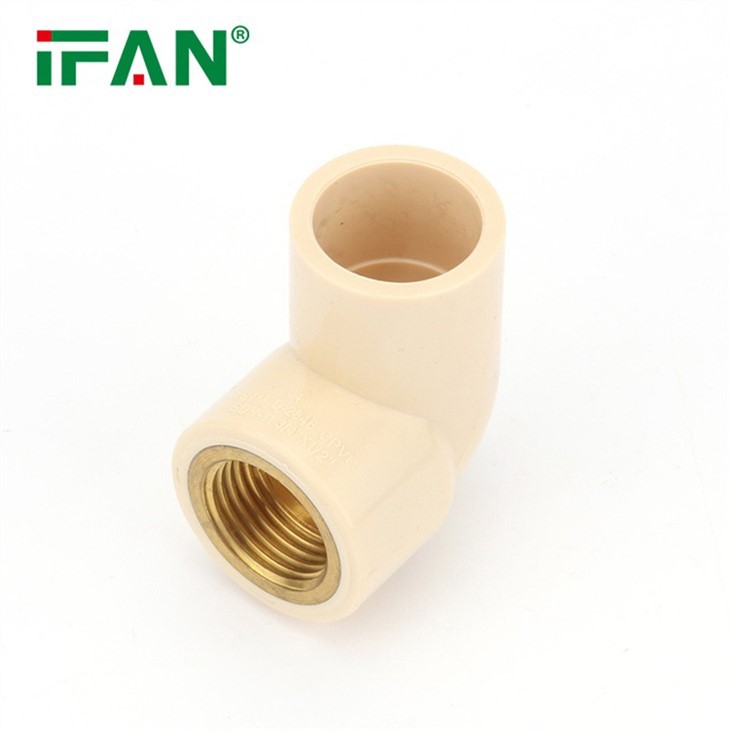

PVC Female Elbow Fitting

Introduction

Static electricity poses a significant challenge in the manufacturing and handling of PVC pipe fittings, leading to issues such as dust accumulation, material sticking, and even safety hazards. In this article, we will discuss the importance of static electricity protection for PVC pipe fittings and strategies to mitigate its effects effectively.

Understanding the Impact of Static Electricity

Static electricity can accumulate on PVC surfaces during processing, handling, and storage, leading to various problems. Dust and particulate matter are attracted to charged surfaces, resulting in contamination and product defects. Additionally, static charges can cause PVC components to stick together, leading to handling difficulties and production delays. Furthermore, static discharge poses a safety risk, especially in environments where flammable materials are present. Understanding the root causes and effects of static electricity is crucial for implementing effective prevention and mitigation measures.

Implementing Static Dissipation Techniques

Several techniques can be employed to dissipate static electricity and prevent its accumulation on PVC pipe fittings. One common approach is the use of antistatic additives in PVC formulations, which help reduce surface resistance and facilitate the discharge of static charges. Incorporating conductive materials such as carbon black or metallic powders into PVC compounds can effectively enhance conductivity and dissipate static electricity. Additionally, applying topical antistatic agents or coatings to PVC surfaces helps create a conductive layer that facilitates charge dissipation.

Controlling Environmental Conditions

Environmental factors play a significant role in static electricity generation and accumulation. Controlling humidity levels in manufacturing and storage facilities can help mitigate static electricity issues associated with dry air conditions. Increasing humidity levels reduces the likelihood of static charge buildup on PVC surfaces by promoting moisture absorption and conductivity. Furthermore, maintaining proper ventilation and airflow within production areas helps dissipate static charges and prevent their accumulation on PVC pipe fittings.

Grounding and Bonding Measures

Grounding and bonding are essential techniques for preventing static electricity buildup and ensuring a safe working environment. Grounding PVC processing equipment, such as extruders and molding machines, helps discharge static charges generated during operation. Additionally, bonding PVC components together using conductive straps or wires ensures that any accumulated static charges are safely discharged, minimizing the risk of electrostatic discharge incidents. Implementing proper grounding and bonding practices is critical for effective static electricity protection in PVC pipe fitting manufacturing.

Training and Awareness Programs

Employee training and awareness programs are vital for promoting a culture of static electricity safety and prevention in PVC pipe fitting production facilities. Educating workers about the risks associated with static electricity and the importance of proper prevention measures helps foster a proactive approach to static control. Training programs should cover topics such as static electricity fundamentals, prevention techniques, emergency procedures, and the proper use of personal protective equipment (PPE). By empowering employees with the knowledge and skills to identify and address static electricity hazards, manufacturers can create a safer and more productive work environment.

Conclusion

In conclusion, static electricity poses significant challenges in the manufacturing and handling of PVC pipe fittings, requiring proactive prevention and mitigation measures. By understanding the impact of static electricity, implementing static dissipation techniques, controlling environmental conditions, employing grounding and bonding measures, and conducting training and awareness programs, manufacturers can effectively protect against static-related issues and ensure a safe and efficient production process. Prioritizing static electricity protection not only enhances product quality and productivity but also safeguards the well-being of workers and the integrity of PVC pipe fitting operations.

Hot Tags: pvc female elbow fitting, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, Aluminum PPR Pipe, Glass Fiber PPR Pipe, PEXA Floor Heating PEX Pipe, Brass Core Ball Valve, Compression Equal Socket, PPR Fitting Male Union

Send Inquiry