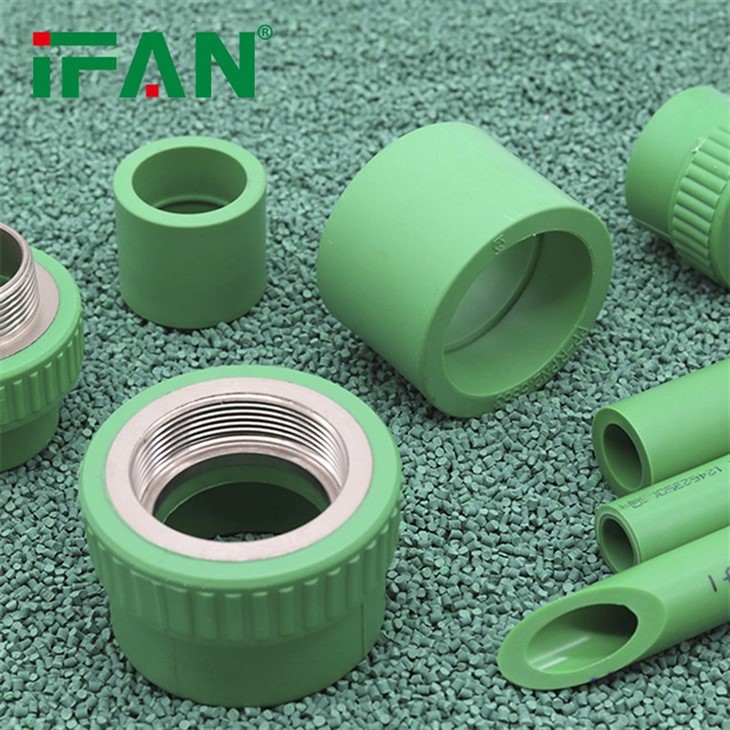

Tomex PPR Fitting

The Pressure Resistance and Load Capacity of PPR Pipe Fittings in Sewage Treatment Systems

Introduction

PPR (polypropylene random) pipe fittings are widely used in sewage treatment systems due to their excellent resistance to chemicals, corrosion, and abrasion. As with any piping system, it is essential to understand the pressure resistance and load capacity of PPR pipe fittings to ensure their durability and safety in operation. In this article, we will explore the pressure resistance and load capacity of PPR pipe fittings in sewage treatment systems.

1. Pressure Resistance

PPR pipe fittings have excellent pressure resistance due to their high molecular weight and superior mechanical properties. The pressure resistance of PPR pipe fittings is typically measured using the hydrostatic test method. This involves subjecting the fittings to water pressure that is higher than their rated pressure for a specified period. If there are no visible signs of deformation or leakage, the fittings are considered to have passed the test. Most PPR pipe fittings have a pressure rating of at least 20 bar, which makes them suitable for use in sewage treatment systems that require high-pressure pipelines.

2. Load Capacity

In addition to pressure resistance, PPR pipe fittings also have excellent load capacity. The load capacity of PPR pipe fittings refers to their ability to withstand external forces such as weight or impact without deforming or breaking. The load capacity of PPR pipe fittings can be affected by various factors such as temperature, duration of load, and installation method. Proper installation and support of PPR pipe fittings can help ensure their load capacity. Additionally, it is essential to consider the expected loads that the fittings will be subjected to in sewage treatment systems when selecting appropriate PPR materials.

3. Impact Resistance

Sewage treatment systems often involve harsh environments that may cause physical damage to the pipeline. PPR pipe fittings have excellent impact resistance due to their high elasticity and toughness. They can absorb the force of impact without cracking or breaking. This impact resistance makes PPR pipe fittings suitable for use in sewage treatment systems where heavy machinery or equipment may come into contact with the pipeline.

4. Chemical Resistance

Sewage treatment systems involve exposure to various chemicals, including acids, bases, and organic compounds. PPR pipe fittings have excellent chemical resistance properties, making them ideal for use in such environments. They are resistant to corrosion and degradation caused by chemical exposure. Additionally, PPR materials are non-toxic, ensuring that they do not contaminate the sewage or harm human health.

5. Thermal Expansion

Temperature changes can cause thermal expansion or contraction of PPR pipe fittings, leading to stress within the pipeline system. However, PPR pipe fittings have low thermal expansion properties compared to other materials such as metal. This low thermal expansion property helps to reduce stress on the pipeline system and minimize the risk of damage. It is essential to consider the expected temperature variations in the sewage treatment system when selecting appropriate PPR materials with suitable thermal expansion properties.

Conclusion

PPR pipe fittings have excellent pressure resistance, load capacity, impact resistance, chemical resistance, and thermal expansion properties, making them suitable for use in sewage treatment systems. Proper selection of PPR materials, installation, and maintenance practices can help ensure their durability and safety in operation. By understanding the pressure resistance and load capacity of PPR pipe fittings, sewage treatment systems can be designed and operated with optimal performance and longevity.

Hot Tags: tomex ppr fitting, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, PPR Fitting Female, PPR Fitting Elbow, PPR Fitting Socket, Pure PPR Fitting, PPR Fitting Cap, PPR Fitting Plug

Send Inquiry