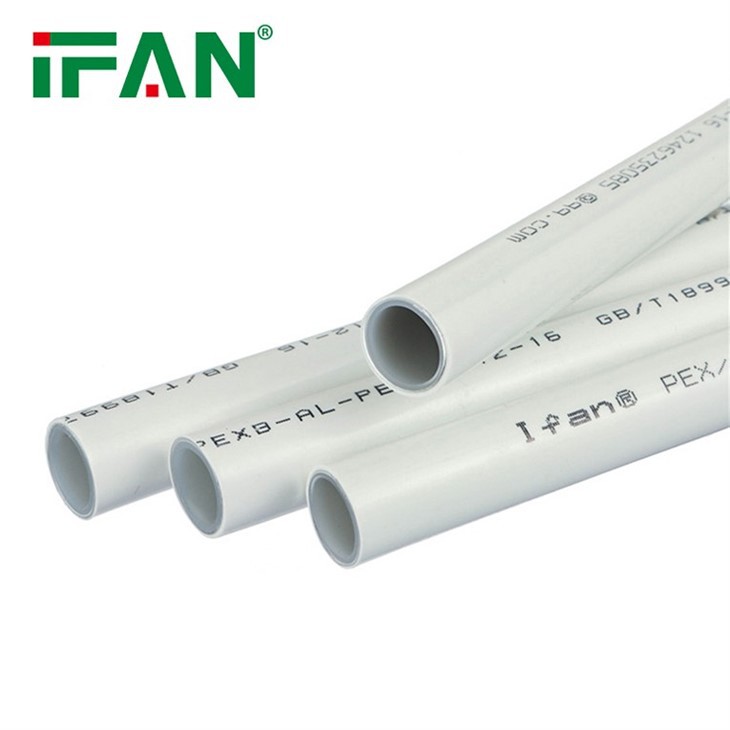

ASTM F1281 Plastic PEX Pipe

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN's product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

Material Formulation and Low-Temperature Processing Optimization for PEX Pipes

Introduction to Material Formulation in PEX Pipes

Material formulation is crucial in determining the performance, flexibility, and durability of PEX (cross-linked polyethylene) pipes. The quality of the raw materials used, along with their precise combination, directly affects how the pipes perform under various conditions, particularly in low-temperature environments. In this article, we will explore the importance of material formulation and low-temperature processing optimization in PEX pipes, comparing IFAN brand PEX pipes with HUIBO brand pipes to illustrate how IFAN's superior approach leads to better product performance.

Optimizing Material Formulation for PEX Pipes

PEX pipes are widely used in plumbing and heating systems due to their flexibility, resistance to chemical corrosion, and ability to withstand high and low temperatures. However, the performance of these pipes is highly dependent on the formulation of the polyethylene material used. A well-balanced formulation ensures that the pipes retain flexibility without compromising their strength, especially in low-temperature environments where brittleness is a concern.

IFAN's material formulation for PEX pipes is designed to optimize these properties. Their pipes use a carefully selected blend of polyethylene with additives that enhance the material's ability to handle cold temperatures without becoming brittle. In comparison, HUIBO's formulation, while effective, may not offer the same level of cold-resistance and flexibility, leading to potential failures in extremely low temperatures. This gives IFAN an advantage in markets where low-temperature performance is critical.

Low-Temperature Processing in PEX Pipe Manufacturing

Low-temperature processing during the manufacturing of PEX pipes is essential for controlling the crystallinity of the polyethylene. This process impacts the pipes' flexibility and strength, as the molecular structure of the material is locked in place during cooling. If cooling is done too quickly or too slowly, it can lead to internal stress and a reduction in the pipe's ability to handle temperature fluctuations.

IFAN employs an optimized low-temperature processing technique that ensures a uniform molecular structure across the pipe wall. This not only improves the pipe's resistance to cracking under stress but also enhances its flexibility in cold environments. On the other hand, HUIBO's processing techniques, though effective, may not be as finely tuned, which can result in inconsistencies in material strength and increased susceptibility to cracking when exposed to low temperatures.

Impact of Material Formulation on Low-Temperature Flexibility

The flexibility of PEX pipes is one of their key benefits, especially in plumbing applications where tight spaces and complex configurations are common. However, maintaining flexibility in low temperatures is a challenge that requires careful attention to both material formulation and processing.

IFAN's PEX pipes exhibit superior flexibility in cold conditions due to the precise formulation of cross-linked polyethylene and the optimization of their low-temperature processing. This results in pipes that can bend and flex without breaking, even when temperatures drop significantly. In contrast, HUIBO's pipes, while functional in moderate temperatures, may become stiffer and more prone to damage in freezing conditions. The difference in performance is a direct result of the material formulation and processing techniques used by each brand.

Durability and Longevity in Low-Temperature Environments

PEX pipes are expected to last for many years, even in challenging environments. Durability, especially in cold regions where pipes are exposed to freezing temperatures, is critical to ensuring that plumbing systems remain reliable over time. Pipes that are not optimized for low-temperature performance can become brittle, leading to cracking or rupturing under pressure.

IFAN's PEX pipes are engineered for longevity, with a focus on ensuring that the pipes maintain their strength and flexibility even after prolonged exposure to cold conditions. Their advanced material formulation and processing techniques minimize the risk of brittleness, ensuring that the pipes continue to perform well throughout their lifespan. HUIBO's PEX pipes, while durable in standard conditions, may show signs of wear and degradation faster in extreme low-temperature environments due to less optimized material formulation and processing methods.

Comparative Analysis of IFAN and HUIBO PEX Pipes

When comparing IFAN and HUIBO PEX pipes, it is clear that IFAN's approach to material formulation and low-temperature processing optimization gives them a significant advantage. IFAN's pipes exhibit superior flexibility, strength, and resistance to low-temperature conditions, making them the preferred choice for cold environments. HUIBO's pipes, while adequate for general use, may not provide the same level of performance in extreme cold, where flexibility and durability are critical.

Conclusion: IFAN's Superior Low-Temperature PEX Pipe Technology

In conclusion, material formulation and low-temperature processing optimization are key factors that determine the performance of PEX pipes in cold environments. IFAN's commitment to using high-quality materials and employing advanced low-temperature processing techniques results in pipes that are more flexible, durable, and reliable in challenging conditions. When compared to HUIBO, IFAN's PEX pipes stand out as the superior option, offering better performance and longevity in low-temperature applications. Through their innovation and attention to detail, IFAN continues to lead the market in high-quality PEX pipe production.

IFAN PEX Pipes: Comprehensive Compliance with International Standards

IFAN PEX pipes not only adhere to the ASTM F1974 series standards but also meet a wide range of other international and national standards, including ASTM F1281, CSA B137, DIN 16836, GB18997, ISO 21003, ISO 15875, GB-T 18992, DIN 16892, ASTM F877, ASTM F2788, BS 7291, and BS EN ISO 15875. This extensive certification ensures that IFAN PEX pipes deliver superior performance, reliability, and compatibility in a variety of plumbing and heating systems across the globe.

Hot Tags: astm f1281 plastic pex pipe, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, Stainless Steel Braided Hose, Bathroom Shower Hose, PPR Fitting Socket, Brass Ball Valve, PEX Pipe, PEX Sliding Fitting

Send Inquiry