Introduction

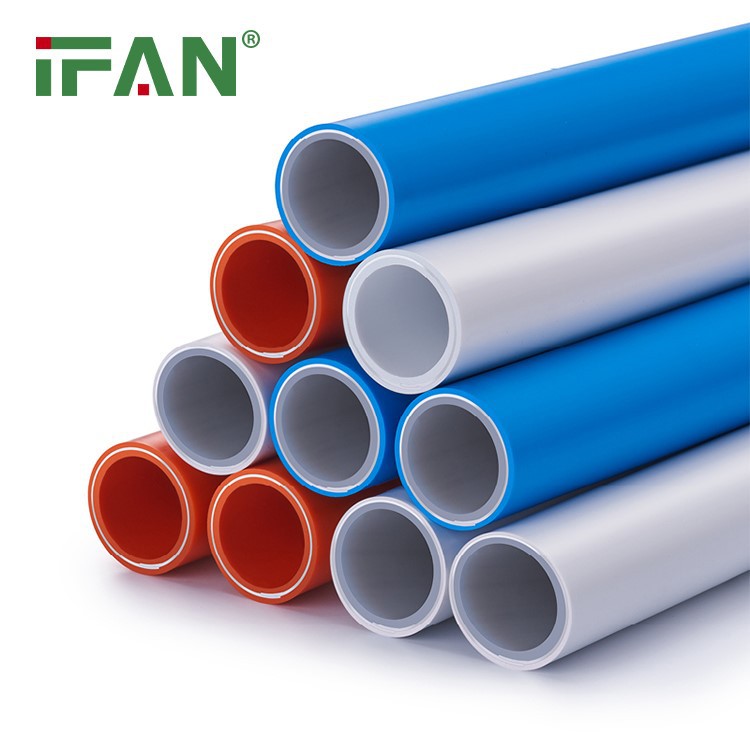

Sunplast Aluminum plastic pipe, also known as PEX-AL-PEX pipe, is a type of multilayer pipe made up of an aluminum core with inner and outer layers of high-density polyethylene (HDPE). It is widely used in hot and cold water supply systems due to its excellent performance in terms of temperature resistance, pressure resistance, and corrosion resistance. This article will elaborate on the process of joining aluminum plastic pipes.IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our YouTube Website:www.YouTube.com

Pipe Cutting

The first step in the jointing process is cutting the pipe. It is essential to use a dedicated pipe cutter for this purpose to ensure a clean, straight cut. The cut end of the pipe should be checked for any burrs or deformities, which need to be removed before proceeding.

Pipe Fitting Preparation

Next, the end of the pipe is prepared for fitting. A special reamer is used to remove the excess HDPE layer from the inside and outside of the pipe, exposing the aluminum layer. This step is crucial as it ensures a secure fit between the pipe and the fitting.

Pipe Insertion

Once the pipe end is prepared, the fitting is inserted into the pipe. The fitting, typically made of brass, is designed to fit tightly within the pipe. A special tool is used to expand the end of the pipe, allowing the fitting to be inserted. Once inserted, the pipe contracts around the fitting, creating a secure, leak-proof joint.

Compression Fitting

In some cases, a compression fitting may be used. This involves placing a compression nut and ring over the end of the pipe before inserting the fitting. Once the fitting is inserted, the nut is tightened onto the fitting, compressing the ring against the pipe and creating a secure joint.

Pipe Clamping

Finally, the joint is clamped using a special clamping tool. This tool applies pressure to the fitting, ensuring a tight fit and a secure, leak-proof joint. The clamping process may be repeated several times to ensure a secure fit.

Conclusion

The process of joining aluminum plastic pipes involves several steps, each of which is critical to ensuring a secure, leak-proof joint. While the process may seem complex, with the right tools and techniques, it can be accomplished efficiently and effectively, resulting in a durable and reliable plumbing system.

Please note: Always follow the manufacturer's instructions when installing and jointing aluminum plastic pipes to ensure proper installation and to maintain the warranty.