Introduction

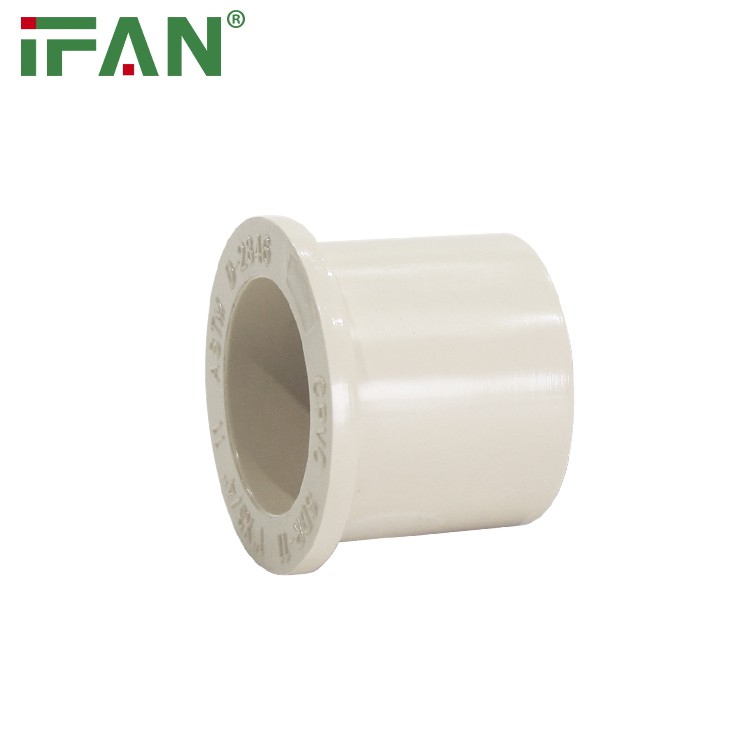

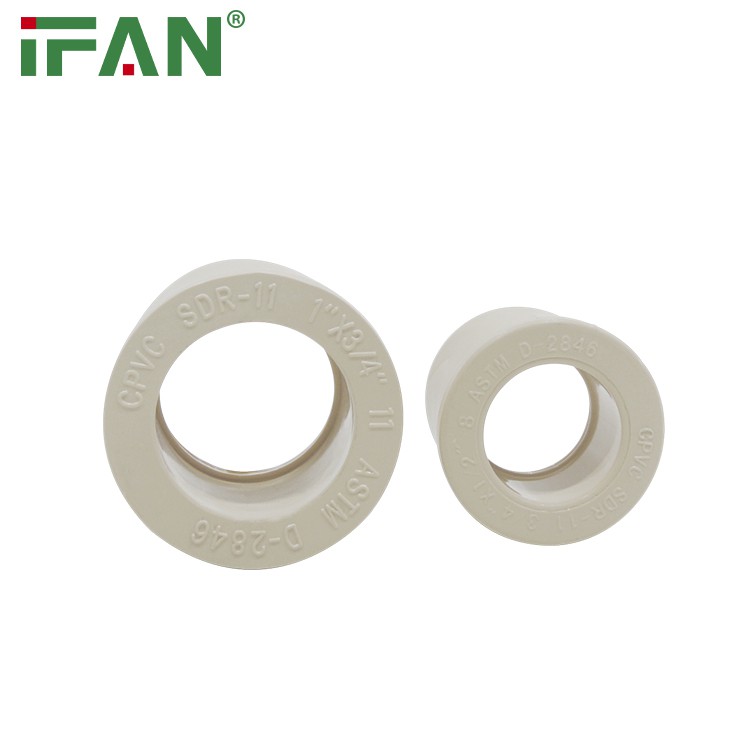

MINGSHI CPVC (Chlorinated Polyvinyl Chloride) pipes are widely used in various industries due to their high temperature and pressure resistance, corrosion resistance, and low thermal conductivity. However, like all pipes, CPVC pipes are susceptible to mechanical failure due to bending or impact stresses. Core filling is a technique that is used to improve the strength and durability of CPVC pipes. In this article, we discuss the role of core filling technology in maximizing the performance of CPVC pipes.IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our YouTube Website:www.YouTube.com

The Benefits of Core Filling Technology

Core filling technology involves filling the hollow core of a pipe with a material that has higher compressive strength than the pipe material. The core filling material can be either cement or a polymer-based compound. The following are some benefits of core filling technology:

1.Improved Strength - The primary benefit of core filling technology is improved strength. By filling the core of the pipe with a material that has higher compressive strength than the pipe material, the overall strength of the pipe is increased.

2.Enhanced Durability - Core filling technology also enhances the durability of CPVC pipes. Pipes that undergo core filling are less likely to crack or break, even under extreme conditions.

3.Better Load Bearing Capacity - Core filling technology also improves the load-bearing capacity of CPVC pipes. Pipes that undergo core filling can withstand greater loads without deforming or failing.

4.Improved Resistance to Environmental Factors - Core filled pipes are also more resistant to environmental factors such as temperature fluctuations, chemical exposure, and UV radiation.

The Core Filling Process

The core filling process involves drilling holes into the CPVC pipes and injecting a cement or polymer-based compound into the hollow core. The injected material is then allowed to harden and cure, creating a solid core that supports the pipe's structure.

Applications of Core Filled CPVC Pipes

Core filled CPVC pipes are commonly used in industrial applications where pipes are subjected to high loads and extreme environmental conditions. Some industries that benefit from core filled CPVC pipes include:

1.Chemical Processing - Core filled CPVC pipes are commonly used in chemical processing plants where the pipes are exposed to harsh chemicals and high pressure.

2.Water Treatment - Core filled CPVC pipes are also used in water treatment facilities where the pipes are exposed to high temperatures and pressure.

3.Oil and Gas - Core filled CPVC pipes are used in the oil and gas industry where pipes are subjected to high loads and extreme environmental conditions.

Conclusion

Core filling technology is a valuable technique for improving the strength and durability of CPVC pipes. By enhancing the load-bearing capacity and resistance to environmental factors, core filled CPVC pipes can withstand extreme conditions in various industrial applications.