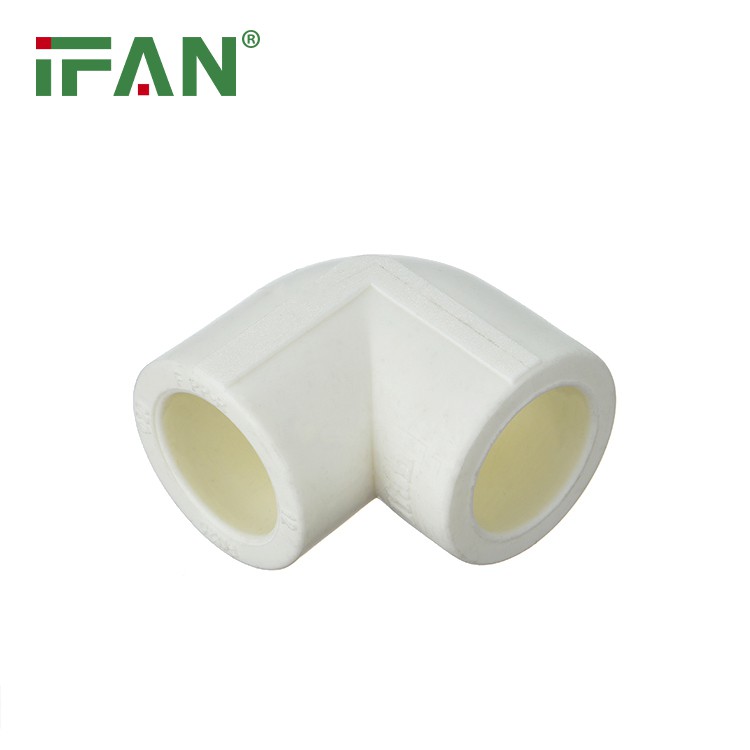

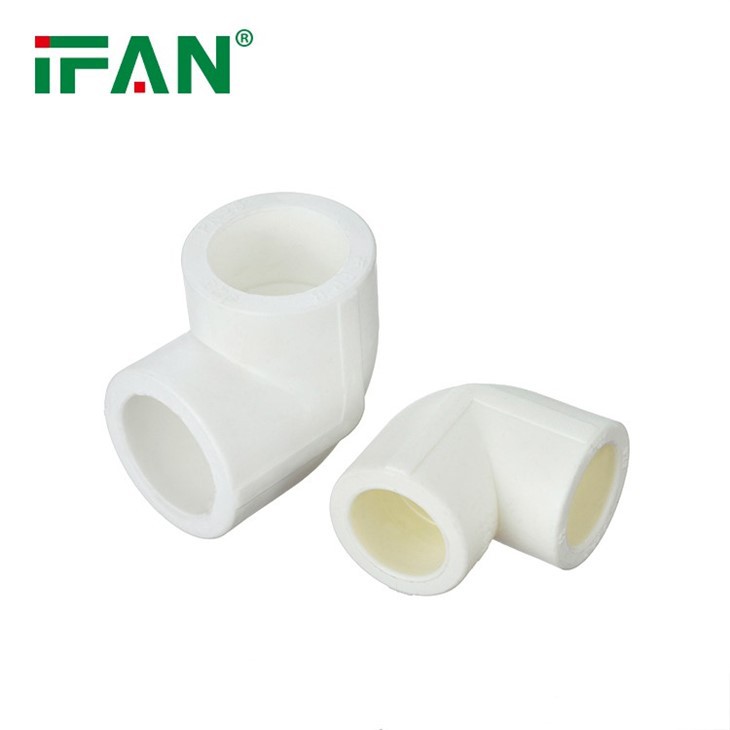

PN25 PPR Pipe Fitting Elbow

Introduction

Polypropylene Random Copolymer (PPR) pipes and fittings are widely used in plumbing and heating systems due to their excellent properties and ease of installation. In this article, we will discuss the welding process for PPR pipes and fittings, as well as the quality control measures for joints, focusing on ensuring reliable and leak-free connections.

Welding Process for PPR Pipes and Fittings

The welding process for PPR pipes and fittings involves several steps to ensure a strong and leak-free joint. Firstly, the surfaces to be joined must be cleaned and deburred to remove any dirt, oil, or rough edges that could compromise the integrity of the weld. Next, the pipes and fittings are heated using a specialized welding tool until the PPR material reaches its melting point. Once sufficiently heated, the pipes and fittings are pressed together firmly to form a fusion bond. Finally, the joint is allowed to cool and solidify, creating a seamless connection between the components.

Quality Control Measures for Joints

Quality control measures are essential to ensure the integrity and reliability of PPR joints. One key aspect is ensuring proper alignment and fit-up of the pipes and fittings before welding. Misalignment or gaps between components can lead to weak joints and potential leaks. Additionally, the welding parameters, such as temperature and pressure, must be carefully controlled to achieve a uniform and robust fusion bond. Visual inspection of the welds is also crucial to identify any defects or irregularities that could compromise the joint's integrity.

Non-Destructive Testing (NDT) Techniques

Non-destructive testing (NDT) techniques are commonly used to assess the quality of PPR joints without causing damage to the components. One commonly used method is visual inspection, where trained inspectors examine the welds for any visible defects or discontinuities. Ultrasonic testing can also be employed to detect internal flaws or voids within the joint by transmitting high-frequency sound waves through the material. These NDT techniques help identify potential defects early on, allowing corrective action to be taken before the joint is put into service.

Importance of Leak Testing

Leak testing is a critical step in quality control to ensure the integrity of PPR joints and prevent water leakage in plumbing systems. Various methods, such as pressure testing and water immersion testing, can be used to assess the leak tightness of the joints. Pressure testing involves pressurizing the system with water or air and monitoring for any pressure drop, indicating the presence of leaks. Water immersion testing, on the other hand, involves submerging the assembled components in water and visually inspecting for any signs of leakage. These tests help verify the reliability of the joints and ensure they meet the required performance standards.

Conclusion

In conclusion, the welding process for PPR pipes and fittings requires careful attention to detail and adherence to quality control measures to ensure reliable and leak-free joints. By following proper welding procedures, implementing quality control measures, and conducting thorough testing, engineers and installers can achieve high-quality connections that meet the demands of plumbing and heating systems. Maintaining the integrity of PPR joints is essential for the long-term performance and durability of the overall piping system.

Hot Tags: pn25 ppr pipe fitting elbow, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, Brass Ball Valve, PPR Fitting, Brass Valve Bibcock, PEX AL PEX Pipe Overlap, Bidet Sprayer, PEX Sliding Fitting

Send Inquiry