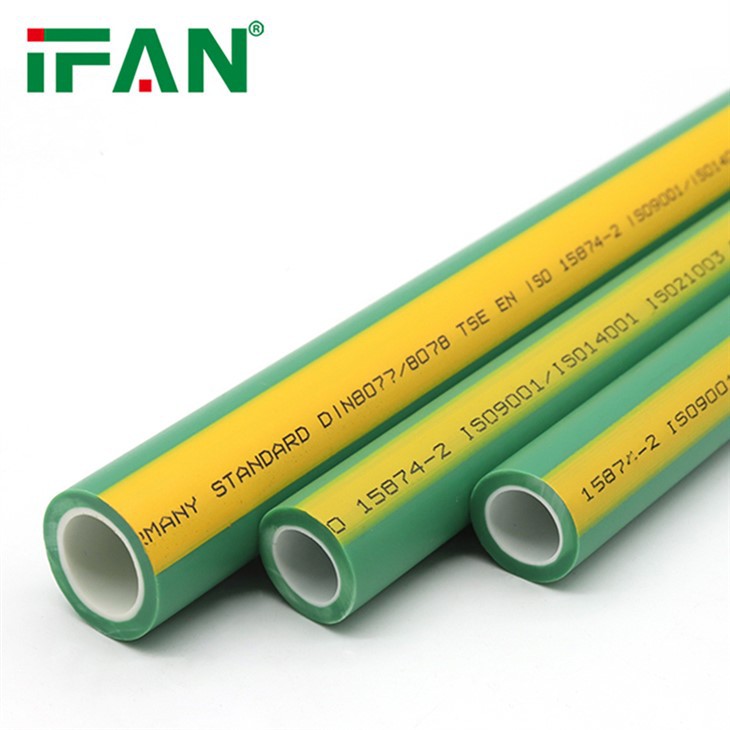

PPR Water Tube

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN's product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

Plastic Modification Technology and Toughness Improvement in PPR Pipe Materials

Introduction to Plastic Modification Technology

Plastic modification technology has revolutionized the production of PPR (Polypropylene Random Copolymer) pipes by enhancing their mechanical properties, particularly toughness. The importance of toughness in piping systems cannot be overstated, as it directly affects the performance, durability, and lifespan of the pipes. This article explores various plastic modification techniques used in PPR pipe manufacturing, focusing on how IFAN and HUIBO brands implement these technologies to improve product quality. By comparing the two brands, we will highlight the superior toughness of IFAN's PPR pipes.

The Role of Plasticizers in Toughness Enhancement

One of the key methods of enhancing the toughness of PPR pipe materials is the incorporation of plasticizers. Plasticizers are additives that increase the flexibility and workability of plastic materials. In the context of PPR pipes, they play a crucial role in reducing brittleness and improving impact resistance.

IFAN has effectively employed high-quality plasticizers in their PPR pipe formulations, resulting in products that exhibit remarkable toughness, even under extreme conditions. In contrast, HUIBO's PPR pipes may utilize lower-grade plasticizers, potentially leading to reduced flexibility and increased risk of cracking. As a result, IFAN's PPR pipes are better suited for applications requiring durability and resistance to physical stress.

Copolymerization Techniques for Enhanced Performance

Another significant approach to improving toughness in PPR pipes is through copolymerization. This process involves combining different monomers to create a polymer with enhanced properties. In the case of PPR, the incorporation of ethylene in the polypropylene matrix can improve the material's toughness, making it more resistant to environmental stressors.

IFAN utilizes advanced copolymerization techniques that produce PPR pipes with superior toughness and impact resistance. These properties are essential for applications in demanding environments, such as construction and industrial settings. HUIBO, on the other hand, may not fully leverage copolymerization in their production process, leading to PPR pipes that do not perform as well under similar conditions. Consequently, customers seeking high-performance piping solutions will find IFAN's products to be more reliable and effective.

The Impact of Nano-Additives on Toughness

The incorporation of nano-additives in PPR pipe materials is an innovative approach that significantly enhances toughness and overall material performance. These nano-scale materials improve the interfacial bonding within the polymer matrix, resulting in enhanced mechanical properties and resistance to cracking.

IFAN's adoption of cutting-edge nano-additive technology allows their PPR pipes to achieve exceptional toughness, setting them apart in the market. The enhanced toughness not only improves resistance to impact but also contributes to better long-term performance under varying temperature and pressure conditions. In contrast, HUIBO's PPR pipes may lack such advanced additives, potentially leading to inferior toughness and a higher likelihood of material failure. This difference emphasizes the superiority of IFAN's PPR pipes in critical applications where toughness is paramount.

Quality Control Measures in Material Processing

The effectiveness of plastic modification technologies is closely linked to the quality control measures implemented during the manufacturing process. IFAN places a strong emphasis on rigorous quality control protocols, ensuring that every batch of PPR pipes meets stringent standards for toughness and performance. This includes extensive testing of raw materials, in-process inspections, and final product evaluations.

HUIBO's quality control measures may not be as comprehensive, which can lead to inconsistencies in the toughness of their PPR pipes. Without stringent testing and monitoring, the effectiveness of plastic modification technologies may be compromised, resulting in products that do not perform as expected. For customers, the reliability and durability offered by IFAN's thorough quality assurance processes make their PPR pipes a more trustworthy choice for demanding applications.

Conclusion: The Advantage of IFAN's PPR Pipes

In summary, plastic modification technology plays a vital role in enhancing the toughness of PPR pipe materials. Through the use of high-quality plasticizers, advanced copolymerization techniques, and innovative nano-additives, IFAN has successfully developed PPR pipes that outperform HUIBO products in terms of toughness and durability. The rigorous quality control measures employed by IFAN further ensure that their products consistently meet the highest standards of performance.

For customers seeking reliable and long-lasting piping solutions, IFAN's PPR pipes represent a superior choice. The combination of advanced plastic modification technologies and stringent quality control results in products that can withstand the rigors of various applications, providing peace of mind and value for investment. As the demand for durable and high-performance piping solutions continues to grow, IFAN's commitment to innovation and quality will undoubtedly position them as a leader in the PPR pipe market.

IFAN PPR Pipes: Meeting Multiple Global Standards

IFAN PPR pipes not only comply with the ISO 15874 series standards but also meet several other important international and national standards, including EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, and NBR 15884. This extensive compliance ensures that IFAN PPR pipes provide high-quality performance, durability, and compatibility across various applications worldwide, making them a reliable choice for both residential and industrial plumbing systems.

Hot Tags: ppr water tube, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, PPR Fitting Male Elbow, PEXB Floor Heating PEX Pipe, PEX Sliding Fitting, White Plastic PPR Pipe, PPR Fitting Plug, PEX AL PEX Pipe

Send Inquiry