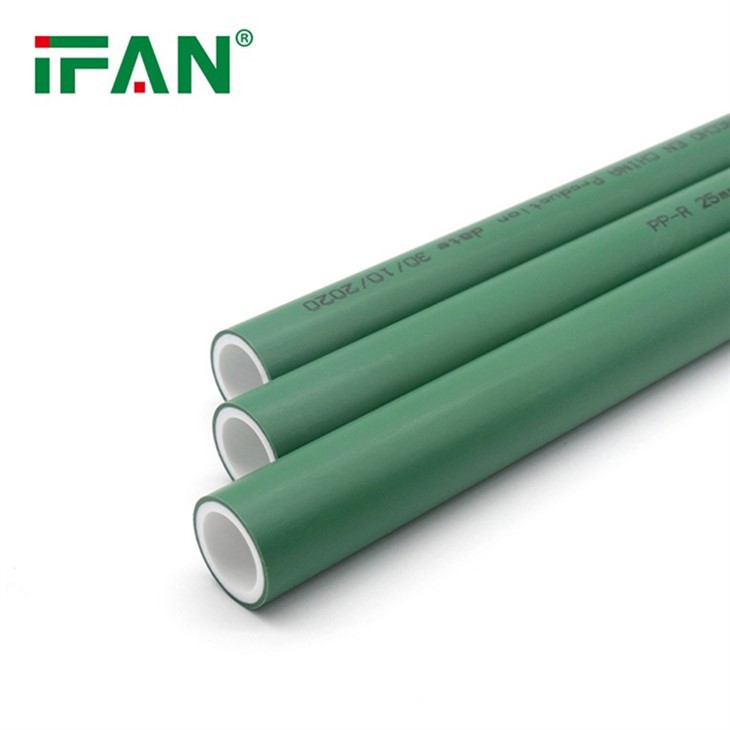

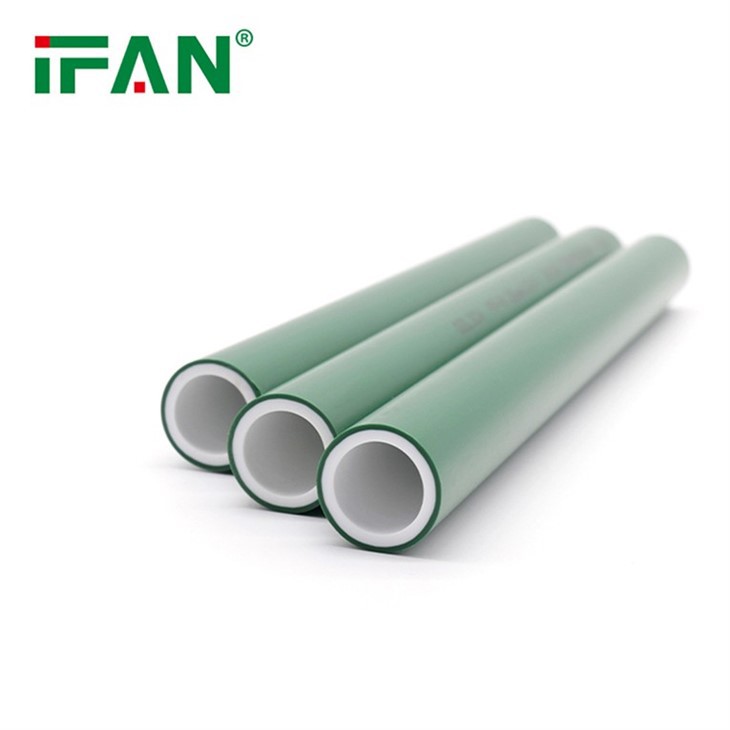

Plastic Plumbing Pipe

IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com,Click to watch IFAN's product video.Compared with Tomex products, our IFAN products from quality to price are your best choice, welcome to buy!

Cold Forming Process and Its Impact on Pipe Strength in PPR Pipes

Introduction to Cold Forming in PPR Pipes

Cold forming is a widely used technique in the production of PPR (Polypropylene Random Copolymer) pipes, primarily for enhancing the strength and resilience of the material without applying heat. Unlike traditional hot-forming methods, cold forming preserves the inherent properties of PPR materials, often improving durability and minimizing thermal stress. This article delves into the cold forming process's advantages, its effect on pipe strength, and a comparison between IFAN and HUIBO PPR pipes, highlighting IFAN's superiority in terms of structural integrity and strength.

Advantages of Cold Forming Over Traditional Methods

Cold forming offers distinct advantages over hot-forming processes, particularly in PPR pipe production. This technique minimizes the risk of thermal degradation, allowing the PPR pipes to retain better chemical stability and structural consistency. Additionally, cold forming leads to a denser and more uniform material composition, enhancing the pipe's overall strength.

IFAN's PPR pipes benefit significantly from advanced cold forming processes, enabling their pipes to maintain high strength and durability across a range of applications. In contrast, HUIBO's PPR pipes may rely more on conventional hot-forming techniques, which can occasionally compromise material consistency and increase susceptibility to long-term wear. IFAN's approach results in PPR pipes that exhibit higher resilience and better performance under high pressure or varying temperatures, setting them apart as a superior choice in the market.

Enhanced Material Strength and Fatigue Resistance

The cold forming process helps increase the fatigue resistance of PPR pipes, a crucial factor in systems where pipes are exposed to repeated stresses over time. By aligning the molecular structure of the PPR material, cold forming allows for greater resistance to cracking and mechanical fatigue, enhancing the pipe's lifespan.

IFAN's dedication to optimizing cold forming ensures that their PPR pipes maintain high fatigue resistance, making them ideal for applications with fluctuating pressure levels or constant flow. On the other hand, HUIBO's PPR pipes, which may not benefit from the same level of cold-forming precision, might demonstrate slightly reduced fatigue resistance. As a result, IFAN pipes offer a longer service life and a reduced need for maintenance or replacements in demanding installations.

Precision in Dimensional Stability and Uniformity

Cold forming also has a significant impact on the dimensional stability and uniformity of PPR pipes. The process improves control over pipe dimensions, ensuring that each section is consistent in thickness and structure. This is essential for efficient and reliable installations, as any inconsistencies can lead to weak points that may impact performance under pressure.

IFAN's advanced cold-forming technology achieves high dimensional accuracy, ensuring that their PPR pipes meet precise standards and maintain uniformity across all segments. This provides an advantage over HUIBO's PPR pipes, which may exhibit minor variations due to less precise forming processes. The greater uniformity in IFAN pipes contributes to a reliable installation, reducing the likelihood of leaks and ensuring consistent pressure handling throughout the system.

Lower Material Stress and Enhanced Durability

The cold forming process imposes less stress on PPR materials compared to hot forming, as it eliminates the need for high temperatures that can introduce residual stresses in the material. Lower material stress results in pipes that are less prone to deformation and warping over time, which is essential for maintaining a stable pipeline structure.

IFAN capitalizes on this benefit by using cold-forming techniques that minimize residual stress and improve overall durability. Consequently, their PPR pipes are better suited for long-term applications where durability is essential. Conversely, HUIBO's hot-formed PPR pipes may experience slight deformations or stress-related weaknesses over time, especially in high-stress environments. This gives IFAN a clear advantage in providing durable and structurally sound PPR pipes for various industrial and residential applications.

Conclusion: The Superiority of IFAN PPR Pipes Through Cold Forming

In summary, the cold forming process is a highly effective technique that enhances the strength, durability, and reliability of PPR pipes. Through careful control of the cold forming process, IFAN has managed to produce PPR pipes with superior mechanical properties, setting them apart from competitors like HUIBO. IFAN's pipes benefit from enhanced fatigue resistance, dimensional stability, and reduced residual stress, making them the preferred choice for demanding applications where pipe strength and longevity are critical.

As a result, IFAN's PPR pipes stand out as a reliable and high-performing solution in the piping industry. The brand's commitment to innovative cold forming and quality control offers customers peace of mind, knowing they are investing in piping products that deliver exceptional strength, resilience, and value over time.

IFAN PPR Pipes: Meeting Multiple Global Standards

IFAN PPR pipes not only comply with the ISO 15874 series standards but also meet several other important international and national standards, including EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, and NBR 15884. This extensive compliance ensures that IFAN PPR pipes provide high-quality performance, durability, and compatibility across various applications worldwide, making them a reliable choice for both residential and industrial plumbing systems.

Hot Tags: plastic plumbing pipe, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, Glass Fiber PPR Pipe, Pure PPR Fitting, Plastic PPR Pipe, Water Plastic PPR Pipe, PPR Fitting Tee, PEX Sliding Fitting

Send Inquiry