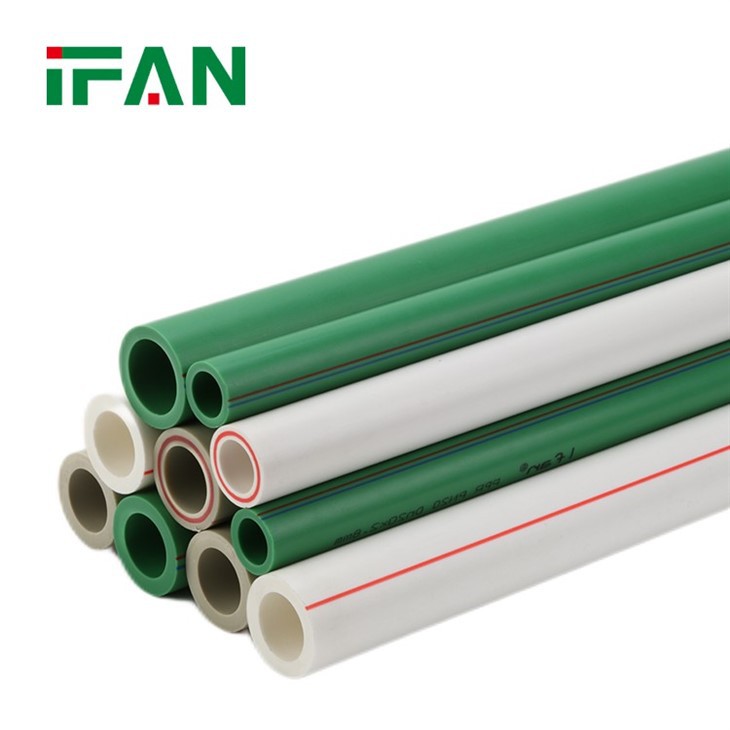

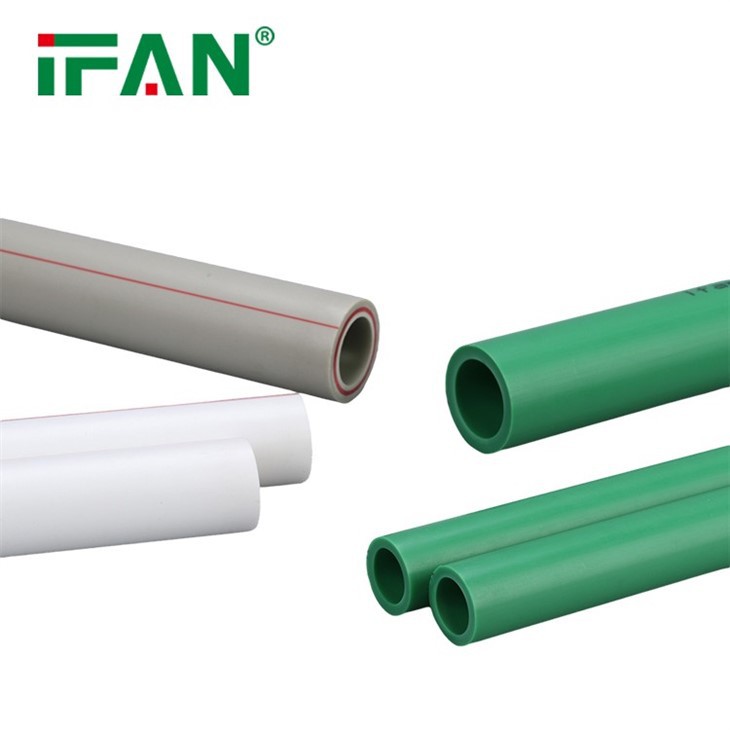

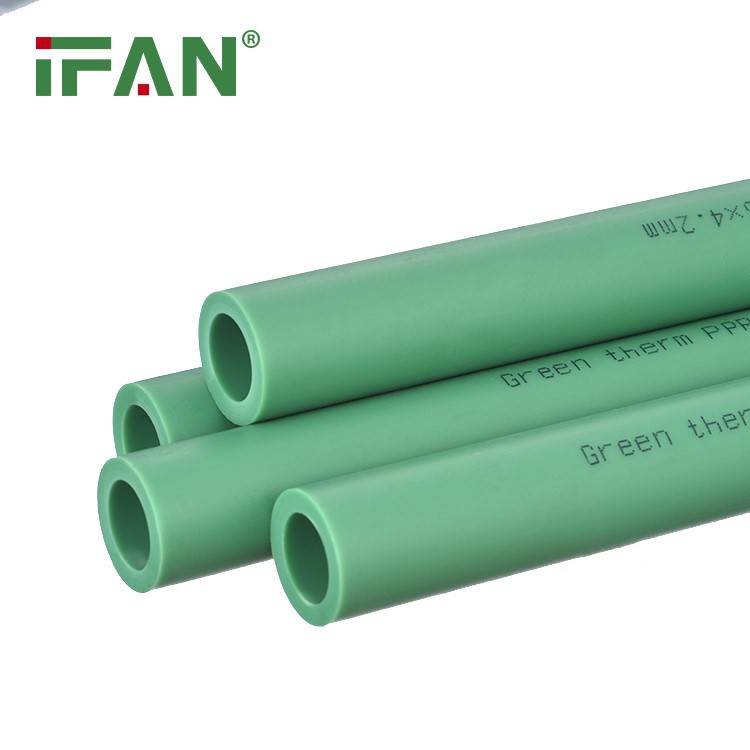

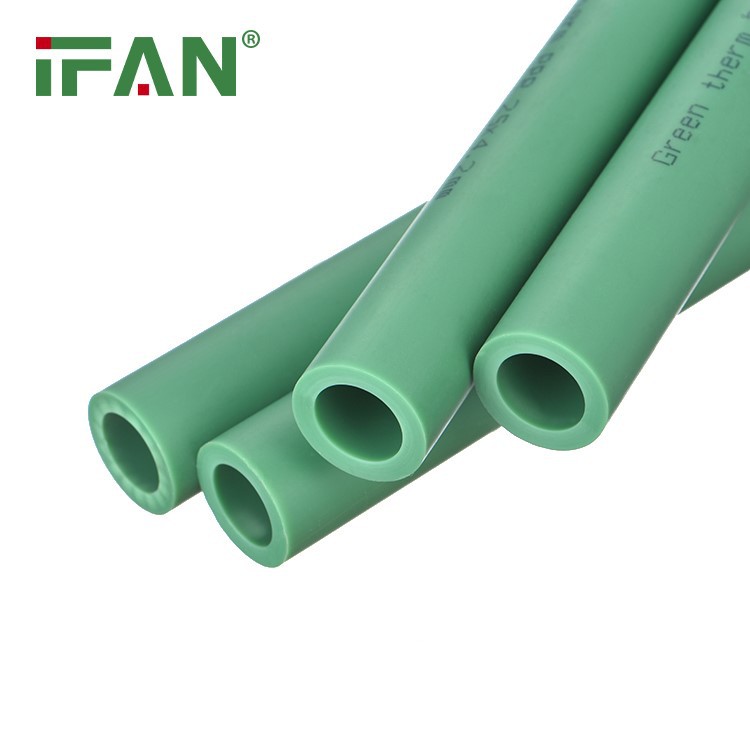

PPR Water Tubes

PPR (Polypropylene Random) water tubes are widely used in plumbing and water supply systems due to their excellent properties, such as high resistance to corrosion, chemical reactions, and scaling. Here is a step-by-step guide on how to use PPR water tubes:

Planning and Design: Before starting the installation process, it is important to plan and design the plumbing system properly. Consider factors such as the layout, water flow requirements, and connections to ensure efficient water distribution. Determine the lengths and sizes of PPR water tubes needed for the project.

Tools and Materials: Gather all the necessary tools and materials for the installation. This includes PPR water tubes of the required lengths and diameters, PPR fittings such as elbows, tees, and connectors, a pipe cutter, a welding machine, welding rods, a deburring tool, and a measuring tape.

Preparation: Make sure the worksite is clean and free from any obstructions. Prepare the PPR water tubes by cutting them to the desired lengths using a pipe cutter. Ensure that the cut ends are clean and free from burrs. Use a deburring tool to remove any rough edges or burrs from the cut ends.

Welding: PPR water tubes are typically joined using a heat fusion welding technique. Start by heating the welding machine to the recommended temperature specified by the manufacturer. Insert a welding rod into the heating element until it melts. Be cautious while handling the hot welding rod.

Connection: Place the heated welding rod into the socket end of the PPR fitting. Insert the PPR water tube into the other end of the fitting. Make sure the PPR tube is inserted completely, ensuring a secure connection. Hold the fitting and tube in place until the joint cools down and solidifies.

Alignment: Ensure proper alignment of the PPR water tubes and fittings. This is important to maintain a seamless flow of water and prevent leaks or blockages. Use a measuring tape or level to check the alignment and adjust if necessary.

Support and Bracing: Provide adequate support and bracing for the PPR water tubes. This helps to prevent sagging, stress, and strain on the pipes. Use pipe hangers, clamps, or brackets to secure the tubes to walls or other structural elements. Ensure proper spacing between the supports to maintain stability.

Pressure Testing: Once the installation is complete, it is recommended to conduct a pressure test to ensure the integrity of the system. Close all the valves and connect a pressure testing device to the system. Gradually increase the pressure to the recommended level and monitor for any leaks or abnormalities. Fix any issues before proceeding.

Insulation: Consider applying insulation material to the PPR water tubes, especially in areas prone to temperature variations or freezing conditions. Insulation helps to prevent heat loss, condensation, and potential damage to the pipes.

Maintenance: Regular maintenance of the PPR water tube system is essential to ensure its longevity and optimal performance. Inspect the system periodically for any leaks, damages, or signs of wear. Replace any faulty components or pipes as needed.

It is crucial to follow the specific manufacturer's guidelines and local plumbing codes during the installation process. If you are unsure or lack experience, it is advisable to seek professional assistance to ensure a safe and efficient installation of PPR water tubes.

Hot Tags: ppr water tubes, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, Glass Fiber PPR Pipe, Aluminum PPR Pipe, PPR Fitting

Send Inquiry