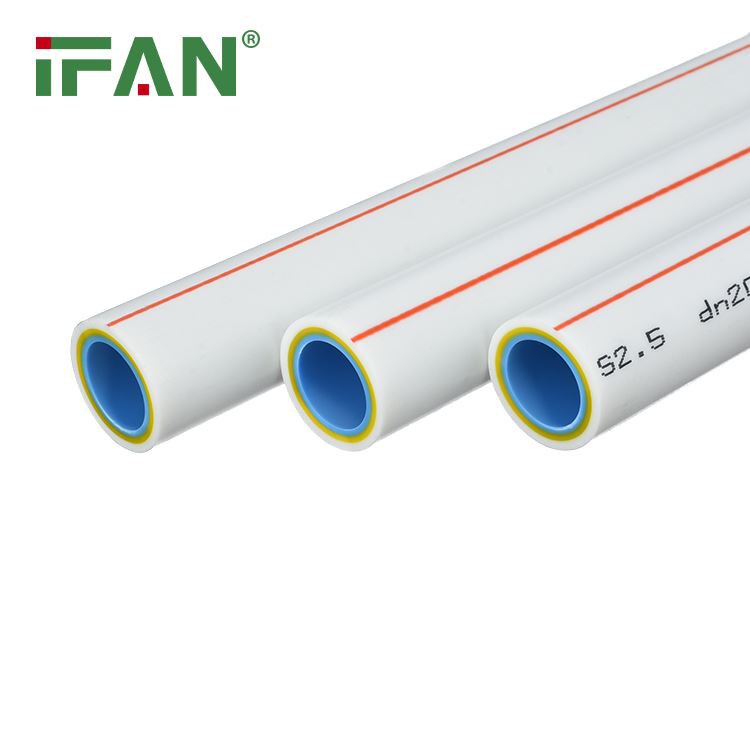

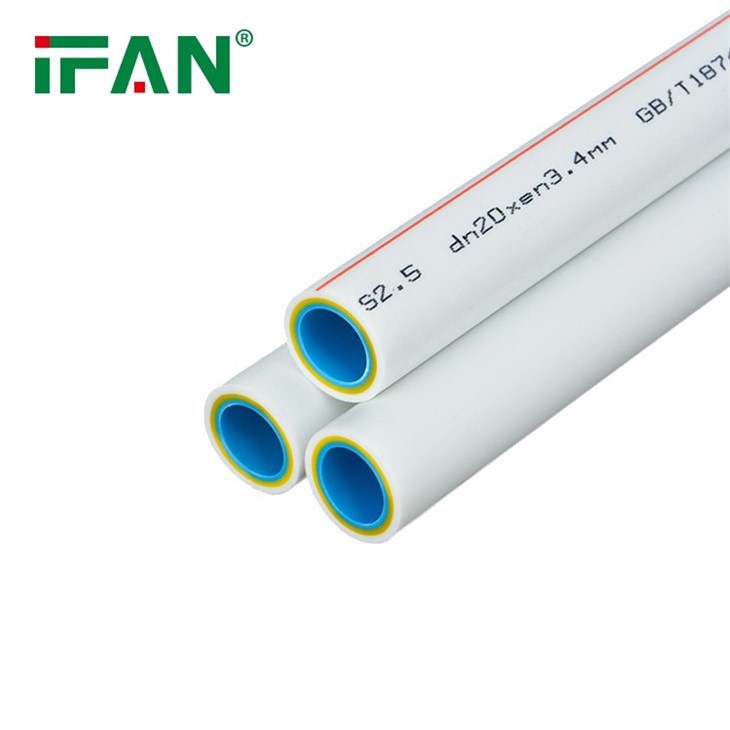

SAM-UK PLastic PPR Pipe

Rheological Properties and Pipeline Design Optimization of PPR Pipes

Introduction:

PPR (Polypropylene Random) pipes are widely used in various industries due to their excellent properties, such as high chemical resistance, low thermal conductivity, and long service life. To maximize the performance of PPR pipes, it is crucial to understand their rheological properties and optimize pipeline design. This article aims to discuss the rheological characteristics of PPR pipes and how they can be utilized to optimize pipeline design.

1. Rheological Behavior of PPR Pipes:

The rheological behavior of PPR pipes refers to how the material deforms and flows under different conditions. PPR pipes exhibit a non-Newtonian behavior, meaning that their viscosity changes with shear rate. Understanding the flow behavior is essential for designing efficient pipelines. Rheological tests, such as melt flow rate (MFR) and capillary rheometry, can provide valuable information about the flow properties of PPR pipes.

2. Effects of Temperature and Pressure on Flow Performance:

Temperature and pressure have a significant influence on the flow performance of PPR pipes. Higher temperatures reduce the viscosity of PPR, resulting in increased flow rates. However, excessive temperature can lead to material degradation. Pressure affects the flow resistance, and high-pressure variations may cause pipe failures. Therefore, optimizing the temperature and pressure conditions is crucial to ensure optimal flow performance and pipe longevity.

3. Pipeline Design Considerations:

To optimize pipeline design, several factors need to be considered. Firstly, the diameter and length of the pipes should be carefully selected to minimize frictional losses and pressure drops. Secondly, the layout and orientation of the pipeline should be designed to avoid excessive bends and restrictions that could hinder fluid flow. Additionally, proper support and anchoring systems should be implemented to prevent sagging or misalignment of the pipes, which could affect flow efficiency.

4. Flow Control and Monitoring:

Flow control and monitoring systems play a vital role in maintaining optimal flow performance in PPR pipelines. Flow control valves and pressure regulators can be installed to adjust the flow rate and maintain steady pressure levels. Flow meters and pressure sensors enable real-time monitoring of the flow characteristics, helping to detect any abnormalities or blockages in the pipeline. Regular maintenance and inspections are necessary to ensure the long-term reliability of the system.

5. Future Trends and Innovations:

The field of PPR pipe design and optimization is continuously evolving. Researchers and manufacturers are exploring innovative materials and additives to improve the rheological properties and overall performance of PPR pipes. Advanced computational fluid dynamics (CFD) modeling techniques are being used to simulate and optimize flow patterns in pipelines. Additionally, the integration of smart technologies, such as IoT-enabled sensors and automated control systems, is expected to further enhance the efficiency and reliability of PPR pipelines in the future.

Conclusion:

Optimizing the flow performance of PPR pipes through an understanding of their rheological properties is essential for efficient pipeline design. By considering factors like temperature, pressure, pipeline layout, and flow control, engineers can ensure optimal flow rates, minimal pressure drops, and prolonged pipe lifespan. Continuous research and technological advancements will further contribute to the improvement of PPR pipe design and its applications in various industries.

Hot Tags: sam-uk plastic ppr pipe, China, suppliers, manufacturers, factory, wholesale, cheap, discount, low price, in stock, free sample, PEX Fitting, PEXB Floor Heating PEX Pipe, Floor Heating PEX Pipe, PPR Fitting Male Union, PPR Fitting Female Socket, Sanitary Product

Send Inquiry