When it comes to choosing the right type of pipes for plumbing or HVAC applications, there are a few different options available, each with unique benefits and properties. Two popular types of plastic pipes that are widely used in construction and plumbing projects are PPH and PPR pipes. While both are made from different materials, they share some similarities and differences.

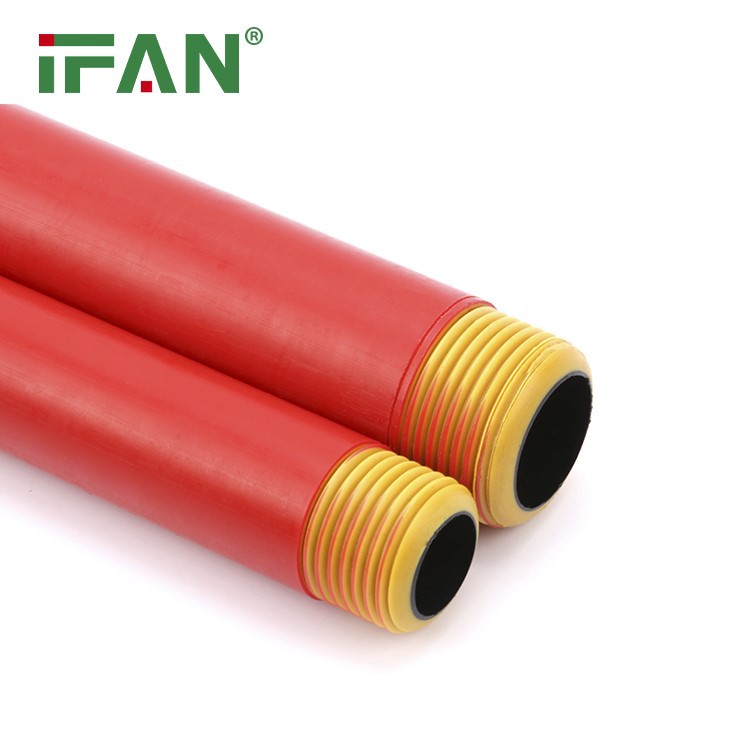

PPH (Polypropylene Homopolymer) Pipes

PPH pipes are made from a thermoplastic material called polypropylene homopolymer, which is a type of plastic that is known for its durability, strength, and resistance to high temperatures and chemical corrosion. PPH is a versatile material that is used in a variety of industries, including packaging, automotive, and construction.

PPH pipes are commonly used in plumbing and HVAC systems as they provide reliable and long-lasting performance. They are resistant to chemical corrosion and can withstand high temperatures and pressures, which makes them ideal for use in industrial and commercial applications. PPH pipes also have good impact resistance, making them perfect for projects where pipes may be exposed to physical stress or impact.

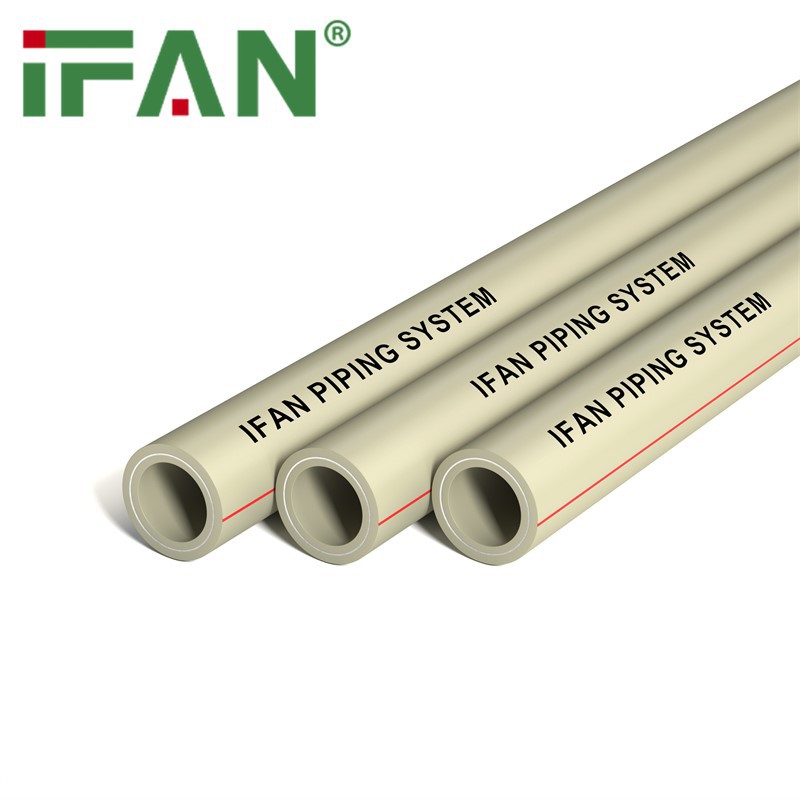

PPR (Polypropylene Random Copolymer) Pipes

PPR pipes, on the other hand, are made from a type of polypropylene called polypropylene random copolymer. This plastic is also known for its strength, durability, and resistance to high temperatures and chemical corrosion. PPR is commonly used in piping systems as it is lightweight, easy to install, and has excellent impact resistance.

PPR pipes are ideal for hot and cold water supply systems, as well as chilled water and HVAC systems. They have excellent resistance to chemical erosion and mechanical wear and tear. PPR pipes are also flexible and easy to install, which makes them ideal for use in projects where space is limited or there is limited access to the installation site.

Similarities and Differences between PPH and PPR Pipes

Both PPH and PPR pipes are made from polypropylene plastic, which means they are lightweight, durable, and resistant to high temperatures and chemical corrosion. These pipes are also eco-friendly as they do not leak harmful chemicals into the environment. However, there are some differences between the two types of pipes. For example:

Material: PPH pipes are made from polypropylene homopolymer, while PPR pipes are made from polypropylene random copolymer. Both types of plastic have different properties and characteristics, which make them suitable for different applications.

Use: PPH pipes are commonly used in industrial and commercial applications where pipes may be exposed to harsh chemicals, high temperatures, and pressures. PPR pipes, on the other hand, are used in residential and commercial projects such as irrigation systems, hot and cold water supply, and HVAC systems.

Flexibility and Installation: PPH pipes are more rigid and less flexible than PPR pipes. This makes them easy to install and less prone to bending or warping. PPR pipes, on the other hand, are more flexible, which makes them ideal for use in projects where there is limited space or limited access to the installation site.

Price: PPH pipes are slightly more expensive than PPR pipes due to their higher resistance to temperature and chemical corrosion.

Conclusion

Choosing the right type of pipes for your plumbing or HVAC project depends on several factors, including the application, environment, and budget. PPH and PPR pipes are both excellent choices for different projects, and their properties make them suitable for different scenarios. While there are some differences between the two types of pipes, they share many similarities and properties that make them popular choices among professionals in the plumbing and construction industry.

When it comes to choosing the right type of pipes for plumbing or HVAC applications, there are a few different options available, each with unique benefits and properties. Two popular types of plastic pipes that are widely used in construction and plumbing projects are PPH and PPR pipes. While both are made from different materials, they share some similarities and differences.

PPH (Polypropylene Homopolymer) Pipes

PPH pipes are made from a thermoplastic material called polypropylene homopolymer, which is a type of plastic that is known for its durability, strength, and resistance to high temperatures and chemical corrosion. PPH is a versatile material that is used in a variety of industries, including packaging, automotive, and construction.

PPH pipes are commonly used in plumbing and HVAC systems as they provide reliable and long-lasting performance. They are resistant to chemical corrosion and can withstand high temperatures and pressures, which makes them ideal for use in industrial and commercial applications. PPH pipes also have good impact resistance, making them perfect for projects where pipes may be exposed to physical stress or impact.

PPR (Polypropylene Random Copolymer) Pipes

PPR pipes, on the other hand, are made from a type of polypropylene called polypropylene random copolymer. This plastic is also known for its strength, durability, and resistance to high temperatures and chemical corrosion. PPR is commonly used in piping systems as it is lightweight, easy to install, and has excellent impact resistance.

PPR pipes are ideal for hot and cold water supply systems, as well as chilled water and HVAC systems. They have excellent resistance to chemical erosion and mechanical wear and tear. PPR pipes are also flexible and easy to install, which makes them ideal for use in projects where space is limited or there is limited access to the installation site.

Similarities and Differences between PPH and PPR Pipes

Both PPH and PPR pipes are made from polypropylene plastic, which means they are lightweight, durable, and resistant to high temperatures and chemical corrosion. These pipes are also eco-friendly as they do not leak harmful chemicals into the environment. However, there are some differences between the two types of pipes. For example:

Material: PPH pipes are made from polypropylene homopolymer, while PPR pipes are made from polypropylene random copolymer. Both types of plastic have different properties and characteristics, which make them suitable for different applications.

Use: PPH pipes are commonly used in industrial and commercial applications where pipes may be exposed to harsh chemicals, high temperatures, and pressures. PPR pipes, on the other hand, are used in residential and commercial projects such as irrigation systems, hot and cold water supply, and HVAC systems.

Flexibility and Installation: PPH pipes are more rigid and less flexible than PPR pipes. This makes them easy to install and less prone to bending or warping. PPR pipes, on the other hand, are more flexible, which makes them ideal for use in projects where there is limited space or limited access to the installation site.

Price: PPH pipes are slightly more expensive than PPR pipes due to their higher resistance to temperature and chemical corrosion.

Conclusion

Choosing the right type of pipes for your plumbing or HVAC project depends on several factors, including the application, environment, and budget. PPH and PPR pipes are both excellent choices for different projects, and their properties make them suitable for different scenarios. While there are some differences between the two types of pipes, they share many similarities and properties that make them popular choices among professionals in the plumbing and construction industry.