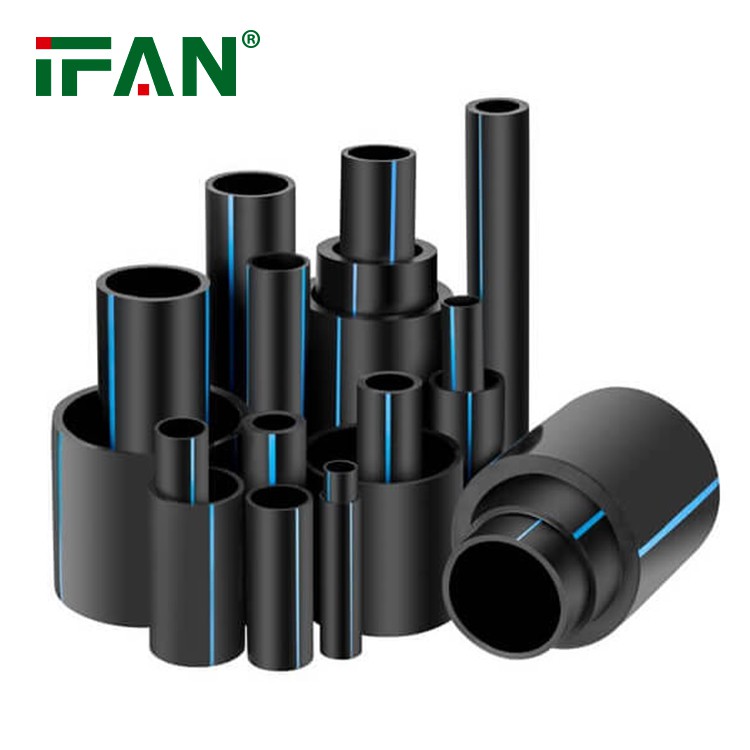

HDPE piping stands for High-density polyethylene piping. It is a type of plastic piping material that is popularly used in a wide range of applications across various industries. HDPE piping is made by melting and extruding high-density polyethylene (HDPE) material, which is a thermoplastic polymer.

HDPE is a highly durable and strong material that can withstand a wide range of extreme weather and environmental conditions. It is resistant to chemicals, abrasion, and impacts, making it ideal for use in various industrial applications. Additionally, HDPE piping is lightweight and flexible, making it easy to handle and install, as well as cost-effective.

Due to its numerous benefits, HDPE piping has become a popular piping solution in various industries, including water management, gas distribution, industrial and agricultural applications, mining, and many others. In this article, we will explore the advantages of HDPE piping in detail and the reasons why this piping solution is becoming increasingly important.

Advantages of HDPE Piping

1. High Durability and Strength: HDPE piping has high durability and strength, which makes it resistant to cracks and damage. This characteristic makes it useful in harsh environments where other materials may break or warp from continuous use, such as in underground or underwater piping systems.

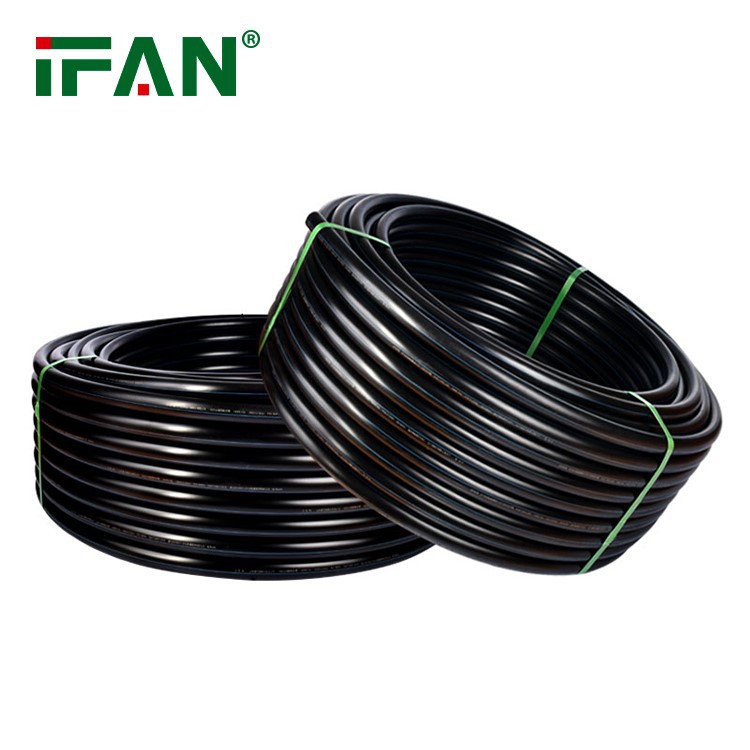

2. Flexibility: HDPE piping has a high level of flexibility, which makes it easy to bend and maneuver during installation. This flexibility also enables HDPE piping to be used in various applications, including uneven terrain or around natural obstacles.

3. Lightweight: HDPE piping is lightweight, which makes it easy to transport, handle, and install. Unlike other pipe materials, the weight of HDPE pipes is light, making it ideal for spaces with high volumes of piping installations.

4. Long Life Span: HDPE piping has a long lifespan, with some manufacturers advertising lifespans of up to 100 years, even when subjected to harsh environmental conditions.

5. Resistance to Chemicals and Corrosion: HDPE piping is resistant to most chemicals and corrosive substances. It does not rot, rust or corrode, making it suitable for use in areas susceptible to chemical impact, such as oil and gas transmission.

6. UV Resistance: HDPE piping is resistant to ultraviolet rays, making it a suitable option for outdoor applications in harsh environments such as wastewater management services, landscaping, and water treatment plants.

7. Energy Efficient: HDPE piping has low friction, which means it is more energy-efficient than other pipe materials. Therefore, it is suitable for use in transmitting fluids at a high velocity while saving energy in the process.

8. Environmentally Friendly: HDPE piping is environmentally friendly, as it can be recycled after use. Unlike other materials such as PVC, it does not release harmful chemicals into the environment during the manufacturing process.

Uses of HDPE Piping

1. Water Management: HDPE piping is widely used in the management of water systems, including irrigation, water supply systems, and wastewater management. The flexibility, high durability, and corrosion resistance make it suitable for use in underground and underwater water systems.

2. Gas Distribution: HDPE piping is used in the transportation of natural gas. The piping material is resistant to damage from exposure to natural elements, including extreme temperatures, underground water, and soil conditions.

3. Industrial Applications: HDPE piping is used in various industrial operations, including mining, chemical processing, and oil and gas transmission. The high durability and resistance to chemicals make the piping a suitable option in harsh industrial environments.

4. Landscaping: HDPE piping is used in landscaping projects, such as irrigation systems and drainage. The piping's flexibility makes it easy to lay and shape into various landscape designs.

5. Agriculture: HDPE piping is used in agricultural operations, such as irrigation systems. The piping's long life span and resistance to abrasion make it suitable for use in harsh agricultural environments.

Conclusion

HDPE piping is becoming increasingly popular in various industries due to its numerous advantages, including high durability, resistance to chemicals, low friction, and environmental friendliness. This piping solution has a long service life and can withstand harsh environmental conditions, making it suitable for underground, underwater, and outdoor applications. HDPE piping is an excellent option for various applications, including water management, gas distribution, industrial and agricultural use, and landscaping.