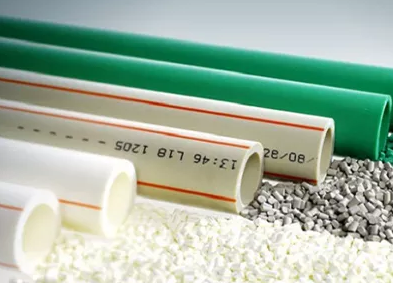

High quality PPR pipe Essential quality

Mechanical properties of

Good mechanical properties are essential elements of high quality PPR pipes. Because it is used in water supply system, PPR pipe needs to withstand certain water pressure for a long time, so the most important mechanical property of PPR pipe is the pressure resistance. There are many factors affecting the mechanical properties of pipes, which are related to equipment and technology, mixing uniformity and raw material performance parameters.

02

Corrosion resistance, anti scaling

Corrosion resistance and anti - scaling are the basic requirements of daily water for pipes. Good PPR pipe has better chemical corrosion resistance, which can resist the erosion of chemical elements in the water. Meanwhile, the smooth inner surface can avoid the formation of scale, making the water delivered more clean and hygienic.

03

High temperature and high pressure

The melting temperature of pure PPR raw material is 220℃. If other impurities are mixed into the raw material during manufacturing, the melting point of the mixture will fall, leading to the decrease of the softening point. This means that pipes tend to soften at lower temperatures, reducing their ability to withstand pressure.

04

Easy to welding

PPR pipes using high-quality PPR raw materials are easier to weld, and the welding opening is expanded evenly during welding, making the welding more solid. Due to the melting point of the PPR water pipe mixed with impurities, the melted part is easy to become dilute and soft during welding, and it is not easy to socket during welding, which affects the welding quality, but also causes the diameter of the water pipe to become smaller, and even causes welding blockage when it is serious.

05

Solid material

The wire mouth of good PPR metal pipe fittings is made of high quality brass material, and the amount of brass will not cut corners, so as to ensure the safe and reliable operation of the pipeline system.